You want the best performance for your products, and sus 304 stainless steel stands out as the clear winner. This grade delivers superior durability and corrosion resistance, especially in harsh or marine environments. While 201 stainless steel offers cost savings, you sacrifice reliability and long-term safety. Quick facts show why most industries choose 304:

-

The 300 series, including 304 and 201, held over 59% of the global stainless steel market share in 2023.

-

The market for stainless steel is growing fast, reaching $197.29 billion by 2030.

|

Property |

Stainless Steel 201 |

Stainless Steel 304 |

|---|---|---|

|

Durability |

Good, less durable |

More durable, reliable |

|

Corrosion Resistance |

Lower |

Higher, ideal for marine |

|

Cost |

Saves money |

Higher due to nickel |

Why Your Stainless Steel Choice Matters

The Heart of Your Product: Material Impacts Performance and Safety

When you choose stainless steel for your products, you make a decision that affects both performance and safety. The grade you select determines how long your product lasts and how well it stands up to daily use. For example, stainless steel 304 offers high corrosion resistance, good strength, and excellent durability. Stainless steel 201 provides moderate corrosion resistance, fair strength, and good durability. Take a look at this comparison:

|

Stainless Steel Grade |

Corrosion Resistance |

Strength |

Durability |

|---|---|---|---|

|

304 |

High |

Good |

Excellent |

|

201 |

Moderate |

Fair |

Good |

|

316 |

Very High |

Excellent |

Excellent |

You see stainless steel in many industries, such as:

-

Food processing

-

Chemical processing

-

Architecture

-

Medical equipment

Your choice of material can even affect user safety. Material failures in medical devices caused 30-40% of FDA recalls in 2013 and 2014. Many of these failures happened because of improper material selection or manufacturing problems. The way you process and store stainless steel also changes how it performs over time.

Not All “Stainless Steel” Is Created Equal

You might think all stainless steel products offer the same quality, but that is not true. Stainless steels fall into different families, such as ferritic, martensitic, austenitic, and duplex. Each family has its own strengths and weaknesses. For example, 304 and 201 both belong to the austenitic group, but their chemical makeup and performance differ.

Stainless steel 304 contains 18% chromium and 8% nickel, which gives it better corrosion resistance and durability than 201. Regular maintenance, like gentle cleaning and avoiding harsh abrasives, helps keep your stainless steel products strong and long-lasting. When you understand these differences, you can make smarter choices for your brand and your customers.

What Is Stainless Steel Type 304?

Defining the Benchmark: Composition of 18/8 Stainless Steel

You often see stainless steel 304 called “18/8” stainless steel. This name comes from its chemical composition—about 18% chromium and 8% nickel. These elements give sus304 its famous shine and strength. The table below shows the official chemical composition of ss304 according to international standards:

|

Standard |

AISI (UNS) |

C, ≤ |

Si, ≤ |

Mn, ≤ |

P, ≤ |

S, ≤ |

Cr |

Ni |

|---|---|---|---|---|---|---|---|---|

|

ASTM A276/A276M |

304 (S30400) |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

18.0–20.0 |

8.0–11.0 |

|

ASTM A240/A240M |

304 (S30400) |

0.07 |

0.75 |

2.00 |

0.045 |

0.03 |

17.5-19.5 |

8.0-10.5 |

This balanced composition makes sus304 the industry standard for quality and reliability.

Key Properties: Corrosion Resistance, Formability, and Durability

You benefit from ss304 because it offers a unique mix of properties:

-

Excellent corrosion resistance, thanks to the chromium and nickel content that forms a protective layer on the surface.

-

Good formability, so you can shape and weld it into many products without losing strength.

-

High durability, which means your products last longer and perform better.

Note: The protective layer on ss304 helps prevent corrosion, but harsh chemicals or salty environments can still cause pitting or crevice corrosion if the surface gets damaged.

The Food-Grade Champion: Ideal for Kitchenware and High-End Products

You find stainless steel 304 in kitchenware, medical tools, and high-end appliances. Its non-reactive surface keeps food pure and safe. Many brands choose ss304 for water bottles and cookware because it does not change the taste of food or drinks. You can trust this material for products that demand both safety and long-lasting performance.

What Is Stainless Steel Type 201?

Composition and Characteristics: The Role of Manganese

You often see stainless steel 201 described as a budget-friendly option. Its composition sets it apart from premium grades. Manufacturers use less nickel and add more manganese to keep costs low and maintain strength. Take a look at the table below to see how each element affects the steel:

|

Composition |

Impact |

|

|---|---|---|

|

Chromium |

16-18% |

Improves resistance to corrosion and adds strength |

|

Nickel |

3-5% |

Boosts formability and corrosion resistance, but less than 304 |

|

Manganese |

5.5-7.5% |

Increases strength, keeps the austenitic structure, and lowers cost |

Manganese plays a key role in 201 stainless steel. You benefit from its ability to enhance strength and keep the steel tough. By using more manganese, manufacturers can reduce nickel content. This change makes 201 stainless steel more affordable for you. Manganese also helps the steel keep its austenitic structure, which means it stays non-magnetic and easy to work with.

Tip: If you want a strong and cost-effective material, 201 stainless steel gives you a good balance by using manganese instead of expensive nickel.

Development and Primary Use Cases: A Cost-Effective Solution

You see 201 stainless steel in many everyday products. Its lower price makes it popular for consumer goods and industrial uses. Here are some common applications:

-

Kitchen sinks and cookware offer affordability and decent corrosion resistance.

-

Decorative architectural elements and railings use 201 for style and moderate weather protection.

-

Automotive parts, such as exhaust systems and trim pieces, rely on its strength-to-weight ratio.

-

Electronics, including computer hardware and mobile phones, benefit from its durability.

-

Medical equipment sometimes uses 201 for surgical instruments and dental tools.

You save money when you choose 201 stainless steel for these products. Manufacturers often pick this grade for items that need good strength but do not face harsh environments.

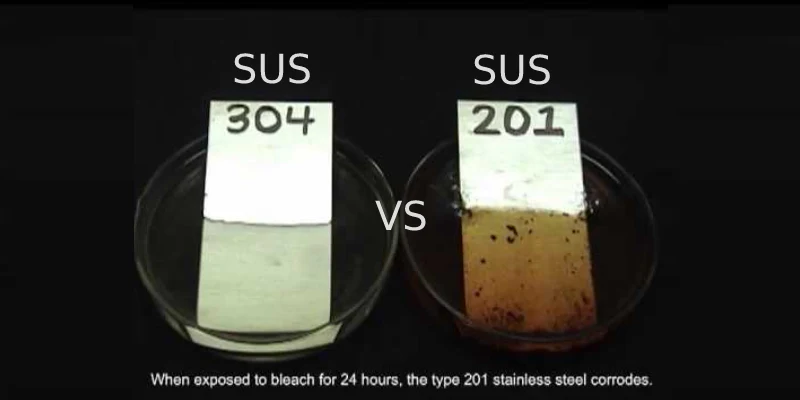

Limitations in Corrosion Resistance: Performance in Challenging Environments

You should know that 201 stainless steel does not match the corrosion resistance of higher grades like 304. In places with high humidity, salt, or chemicals, 201 may show signs of rust or pitting over time. For products exposed to tough conditions, you may want to consider a more corrosion-resistant grade. If your application involves regular contact with water or food, choosing a premium stainless steel can help you avoid problems and keep your products looking new.

SS304 vs. SS201: A Detailed Side-by-Side Comparison

Unit Price: USD 2.50~3.99. Leave online message or send email to info@customizedwaterbottles.com to order

Chemical Composition: Chromium, Nickel, and Manganese Compared

You can see the key differences between ss304 and 201 stainless steel by looking at their chemical composition. The amount of chromium, nickel, and manganese in each type affects their properties and performance. Here is a simple table to help you compare:

|

Element |

201 |

304 |

|---|---|---|

|

Chromium |

16.0-18.0 |

17.5-19.5 |

|

Nickel |

3.5-5.5 |

8.0-10.5 |

|

Manganese |

5.50-7.50 |

2.00 |

SS304 contains more nickel and chromium, which gives it better corrosion resistance. 201 uses more manganese to keep costs low, but this change affects its durability and ability to resist rust.

Material Properties: Corrosion Resistance, Toughness, and Weldability

You want your products to last and perform well. The properties of sus304 and 201 stainless steel show clear differences. Take a look at this comparison:

|

Specification |

201 Stainless Steel |

304 Stainless Steel |

|---|---|---|

|

Corrosion Resistance |

Moderate; prone to rust in harsh environments |

High; excellent resistance to rust and oxidation |

|

Durability |

Good for light to medium use |

Superior strength for heavy-duty applications |

|

Weldability |

Fair, requires skill to avoid warping |

Excellent; easier to weld with consistent results |

-

201 stainless steel may show rust stains after exposure to moisture, while ss304 stays clean and shiny.

-

SS304 sections resist deformation and surface scratches better during impact tests.

-

You will find that ss304 offers great weldability, making it easier to work with and shape.

Tip: If you need a material that stands up to tough conditions and offers long-lasting performance, ss304 is the better choice.

Application and Cost: A Clear Summary of Differences

You should match the right stainless steel to your application and budget. Here is a quick look at the price and use cases:

|

Stainless Steel Type |

Average Price per Ton |

Price Difference |

|---|---|---|

|

201 |

$2,500 |

20-30% less than 304 |

|

304 |

$3,500 |

– |

SS304 costs more, but you get higher resistance to corrosion and better durability. You often see ss304 in food-grade products, medical tools, and high-end kitchenware. 201 stainless steel works well for decorative items, light-duty kitchenware, and products where cost matters most. Always consider the environment and demands of your application before choosing.

SS304 vs. SS201 in Water Bottles: Which One Is Better?

Purity and Taste Assurance: Why 304 Is the Inert Choice

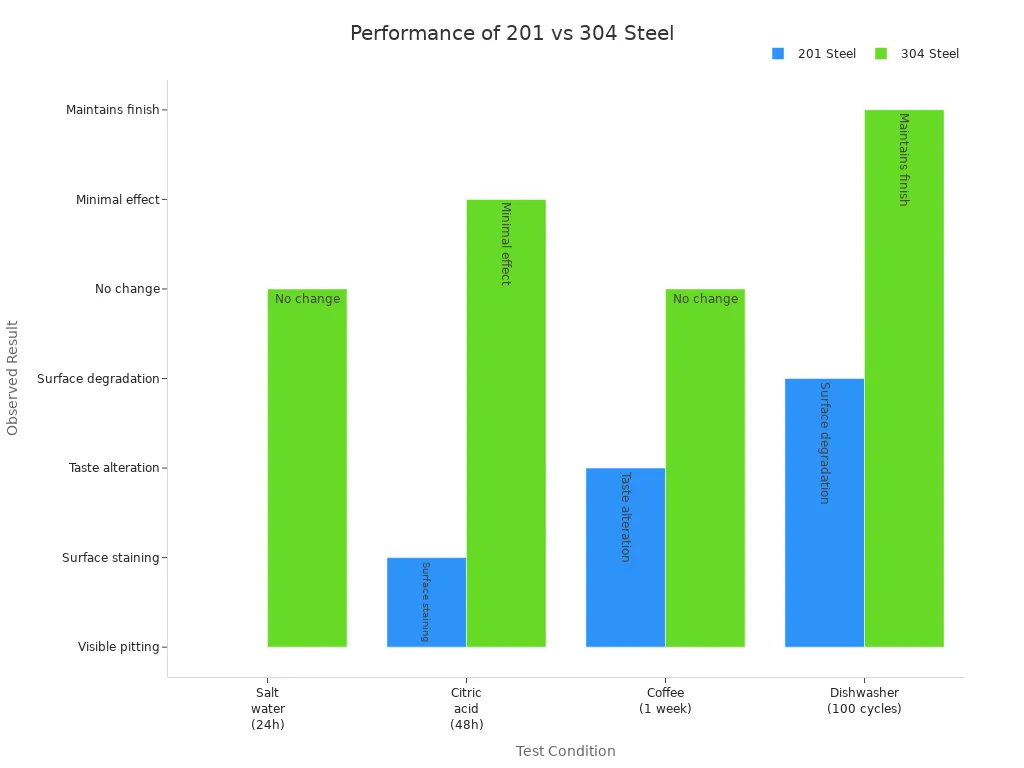

When you choose a water bottle, you want your drink to taste fresh every time. Stainless steel 304 stands out because it is inert and does not react with beverages. You avoid metallic flavors and unwanted odors. Laboratory tests show clear key differences between ss304 and 201 steel:

|

Test Condition |

201 Steel Result |

304 Steel Result |

|---|---|---|

|

Salt water (24h) |

Visible pitting |

No change |

|

Citric acid (48h) |

Surface staining |

Minimal effect |

|

Coffee (1 week) |

Taste alteration |

No change |

|

Dishwasher (100 cycles) |

Surface degradation |

Maintains finish |

You see that ss304 preserves water taste and keeps the bottle looking new. Field studies reveal that 201 steel bottles have a 23% failure rate in the first year, while ss304 bottles show less than 2% failure. Customers often complain about metallic taste and rust with 201 steel, but rarely with sus304.

Safety and Health Considerations: The Food-Grade Standard

You care about safety when you drink from a reusable bottle. Stainless steel 304 meets strict food safety standards worldwide. You find it certified by organizations such as the FDA, NSF, and EFSA. These certifications guarantee that sus 304 stainless steel is safe for food contact and does not leach harmful substances.

|

Certification/Standard |

Description |

|---|---|

|

FDA Compliance |

Ensures material safety for food contact, including cleanliness and non-toxicity. |

|

NSF Certification |

Confirms rigorous standards for food safety and sanitation, including testing for cleanliness and corrosion resistance. |

|

3-A Sanitary Standards |

Sets standards for the design and construction of food processing equipment to ensure sanitary applications. |

|

EFSA Standards |

Regulations in the EU for materials that come into contact with food. |

Long-Term Durability: Resistance to Rust and Pitting Corrosion

You want your bottle to last for years. Stainless steel 304 offers excellent corrosion resistance at room temperature. You avoid rust, pitting, and surface damage even after hundreds of dishwasher cycles. The properties of sus304 make it ideal for daily use. You get a bottle that stays clean and safe, even with acidic drinks or salty water.

Tip: If you want a water bottle that keeps your drink pure and your health protected, choose ss304 for its unmatched durability and resistance.

Conclusion: 304 is the Superior Choice for Quality-Conscious Brands

You see most high-quality water bottles made from 18/8 stainless steel. Experts recommend sus 304 stainless steel for 95% of business applications. You benefit from its superior corrosion resistance, food safety, and long-lasting properties. If you value taste, safety, and durability, stainless steel 304 is the clear winner for your water bottle.

SS304 vs. SS201 in Double-Walled Containers (Vacuum Flasks)

The Insulation Integrity Factor: How Material Affects Vacuum Seal Longevity

When you choose a vacuum flask, you want your drinks to stay hot or cold for hours. The material inside and outside the flask plays a big role in this. SS304 stainless steel helps keep the vacuum seal strong over time. This material does not react with liquids or air, so it keeps its shape and strength. If you use a flask made with 201 stainless steel, you may notice the insulation does not last as long. The metal can weaken or change shape, which lets air in and breaks the vacuum seal. Once this happens, your flask loses its ability to keep drinks at the right temperature.

Why Premium Flasks Use 304 for Both Inner and Outer Walls

You see many top brands use sus304 stainless steel for both the inner and outer walls of their vacuum flasks. They do this for several reasons:

-

304 stainless steel is BPA-free and food-grade, so it does not leach harmful chemicals into your drinks.

-

The material offers high durability and safety for storing food and beverages.

-

Double walls made from 304 stainless steel improve thermal insulation, keeping your drinks hot or cold for longer.

The Risk of Corrosion: How 201 Can Compromise Thermal Performance

Corrosion is a big problem for vacuum flasks. If the inner or outer wall starts to rust, the flask can lose its vacuum seal. SS304 has strong resistance to corrosion, so it protects the vacuum space and keeps the insulation working well. In contrast, 201 stainless steel does not have the same level of protection. Over time, you may see rust spots or pitting, especially if you use the flask with acidic drinks or in humid places. This damage can break the seal and lower the performance of your flask. When you compare the key differences between these two materials, you see that the right application depends on how much you value long-term quality and safety.

Common Myths About Stainless Steel Debunked

Myth 1: “All Stainless Steel Is Rust-Proof”

You may hear that stainless steel never rusts. This idea sounds appealing, but it does not match reality. Stainless steel contains chromium, which forms a thin protective layer on the surface. This layer helps prevent rust, but it is not perfect. If you expose stainless steel to saltwater or acidic liquids, the protective layer can break down. Rust may appear if you leave stainless steel in harsh conditions or do not clean it properly.

-

Stainless steel can rust under certain conditions.

-

Exposure to chlorides, like salt, and high temperatures can damage the protective layer.

-

Improper handling or cleaning can lead to corrosion.

Custom Insulated Portable Stainless Steel Thermos flask 1081604W

Unit Price: USD 2.50~3.99. Leave online message or send email to info@customizedwaterbottles.com to order.

Myth 2: “You Can’t Tell the Difference in Use”

You might think all stainless steel products feel and perform the same. In reality, you can notice differences between grades like 304 and 201. Laboratory tests and user experiences show that 304 stainless steel resists rust and keeps its finish longer. 201 stainless steel may develop stains or lose its shine after repeated use, especially with acidic drinks or in humid environments.

|

Test Type |

Purpose |

Notes |

|---|---|---|

|

Determine the composition of stainless steel grades |

Identifies differences in corrosion resistance and other properties. |

|

|

Portable Analyzers |

Quick on-site analysis of material composition |

Useful for immediate verification of material grade. |

|

Ion Spectroscopy Test |

Detailed analysis of material composition |

Requires a small sample; cost-effective in some regions. |

Note: You can use simple tests or professional analyzers to check the grade of stainless steel before buying.

Myth 3: “The Magnet Test Is a Reliable Quality Check”

You may have heard that using a magnet helps you spot high-quality stainless steel. This test does not always work. Some stainless steels, like 304, are non-magnetic, but magnetism does not guarantee corrosion resistance. 201 stainless steel can also be non-magnetic, yet it does not resist rust as well as 304. The magnet test only tells you about the steel’s structure, not its durability or safety.

-

Magnetism does not determine corrosion resistance.

-

Both 304 and 201 can be non-magnetic.

-

You should rely on chemical analysis or certification for accurate identification.

Remember: Always check product certifications and material specifications to ensure you get the quality you expect.

Conclusion: Investing in Quality and Safety with SUS 304

Summary of Key Advantages: Why 304 is the Professional’s Choice

When you choose sus 304 stainless steel, you invest in a material that stands out for its performance and safety. You benefit from a higher nickel content, which boosts corrosion resistance and extends product life. Manufacturers prefer this grade for its superior strength and hardness. You can rely on its physical properties, even when exposed to high or low temperatures. Kitchenware made from sus304 stainless steel resists rust and keeps food safe, avoiding metallic tastes or stains. You see this material used in a vast array of applications, from food processing equipment to pressure vessels.

-

High corrosion resistance for long-lasting use

-

Superior strength and hardness for demanding tasks

-

Maintains shape and safety at extreme temperatures

-

Trusted by professionals for food-grade and hygiene-critical products

Wholesale Insulated Thermos Stainless Steel Water Bottles with Straw And Paracord Handle1081610W

Unit Price: USD 2.50~3.99. Leave online message or send email to info@customizedwaterbottles.com to order.

A Final Recommendation for Manufacturers and Brands

You should consider your product’s environment and requirements before selecting a stainless steel grade. Experts recommend 304 stainless steel for applications that demand corrosion resistance, hygiene, and longevity. If you need a cost-effective solution for less demanding environments, 201 stainless steel may fit your needs. However, for products exposed to moisture, food, or chemicals, grade 304 remains the top choice.

|

Scenario |

Requirement Analysis |

Recommended Model |

|---|---|---|

|

Outdoor Billboard Frame |

Wind and weather resistance |

304 Stainless Steel |

|

Kitchen Stove and Sink |

Wear resistance, easy cleaning, hygiene |

304 Stainless Steel |

Manufacturers often select sus 304 stainless steel because it adapts easily to fabrication, welding, and machining. You gain peace of mind knowing your products will perform well and last longer.

Anhui iFun‘s Commitment to Premium SUS 304 Material

You want assurance that your products meet global safety standards. Anhui iFun uses premium sus 304 stainless steel and backs its production with certifications such as FDA, RCS, GRS, GLF, and ISCC. You benefit from rigorous FDA and antibacterial testing, ensuring compliance with food safety and BPA-free requirements. This commitment means you receive products that are safe, reliable, and built to last.

You want the best for your products. Stainless steel 304 stands out as the top choice for most industries because of its excellent corrosion resistance and versatility. When you select a grade, keep these factors in mind:

-

Corrosion resistance and strength

-

Formability and cost

-

Suitability for food safety or harsh environments

Experts recommend that you match the steel grade to your project’s needs. Always consider the environment, mechanical demands, and long-term durability before making your final decision.

FAQ

What makes 304 stainless steel better for food and drink containers?

You get better corrosion resistance and purity with 304 stainless steel. This grade does not react with food or drinks. Your water stays fresh and safe. Most food safety standards recommend 304 for direct contact with beverages.

Can you use 201 stainless steel for outdoor products?

You can use 201 stainless steel for some outdoor items. However, you may see rust or stains over time, especially in humid or salty environments. For long-lasting outdoor use, 304 stainless steel works better.

How do you tell the difference between 304 and 201 stainless steel?

You can check the product label or ask for a material certificate. Some portable analyzers test the metal’s composition. The magnet test does not always work. 304 usually costs more and feels heavier.

Is 304 stainless steel dishwasher safe?

Yes, you can safely clean 304 stainless steel in a dishwasher. It resists rust and keeps its shine after many washes. You should avoid harsh cleaners to protect the surface.

Why do some water bottles use 201 stainless steel?

Manufacturers use 201 stainless steel to lower costs. This grade works for budget-friendly products. You may notice more wear or taste changes over time. For premium quality, 304 stainless steel remains the top choice.