Contact Us: +86 13855215327 | info@customizedwaterbottles.com

Wholesale Custom Hydro Vacuum Flask Manufacturer

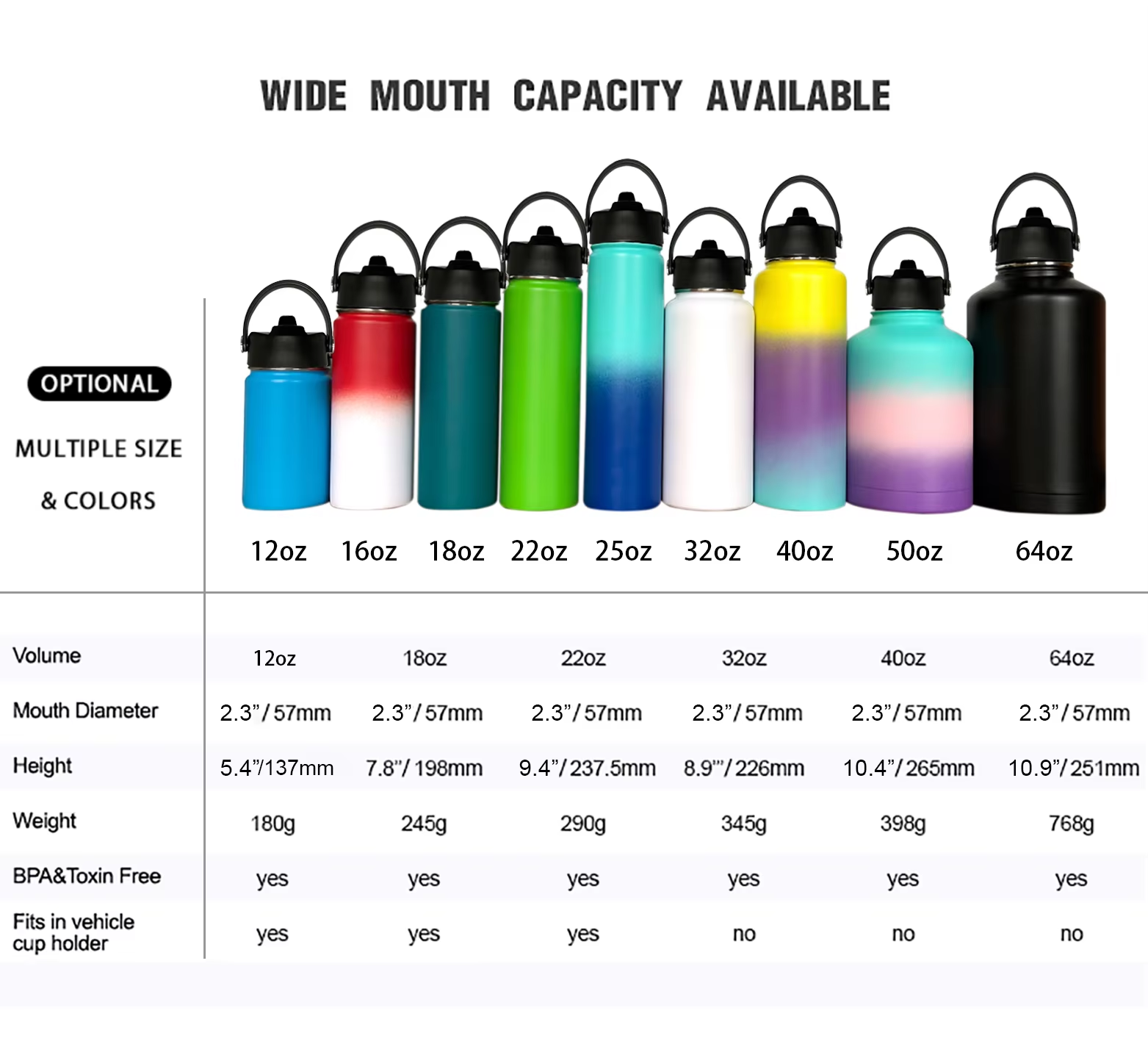

As a leading hydro flask manufacturer, Anhui iFun specializes in producing high-quality stainless steel hydro vacuum flasks designed for style, performance, and durability. We offer wholesale custom hydro vacuum flasks in different sizes, from compact tumblers to large-capacity bottles, all featuring vacuum insulation technology for superior temperature retention. If you’re looking for bulk hydro flask orders, OEM/ODM services, or unique custom hydro flask water bottles, we can provide end-to-end solutions tailored to your brand.

Our thermo hydro flasks are crafted from food-grade, BPA-free materials, ensuring safety and sustainability. With options like sweat-free coating, cusom colors and eco-friendly designs, we help brands and retailers stand out in the market. As a reliable hydroflask supplier, we support hydroflask customization

—whether you need logo (engraving/silk screen printed/ UV printed), custom packaging, or exclusive designs. From metal hydro flask prototypes to mass production, our team ensures seamless manufacturing and timely delivery.

Need a reliable manufacturer for your custom Hydro Vacuum Flask Bottle?

At Anhui iFun, we specialize in high-quality, customizable vacuum-insulated bottles designed to meet your brand’s needs. With advanced manufacturing and strict quality control, we ensure superior thermal performance, durability, and sleek designs—perfect for retailers, distributors, and private labels.

Our team works closely with you to create fully customized flasks, from logo engraving and color finishes to unique shapes and functional upgrades. We use premium 18/8 stainless steel and precision vacuum sealing for optimal temperature retention (hot or cold) while meeting international safety standards.

Whether you need small batches or bulk orders, our flexible production ensures fast turnaround and competitive pricing.

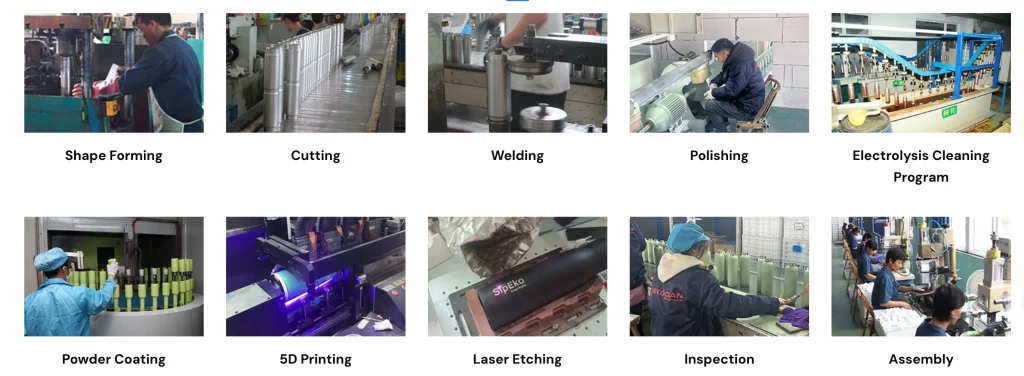

Hydro Flask Manufacturing Process at Anhui iFun

Outer Shell Processing

-

-

Raw material (stainless steel plate or tube)

-

Tube cutting

-

Water expansion shaping

-

Segment division (1 into 2)

-

Expansion forming

-

Middle angle rolling

-

Bottom end shrinking

-

Trimming the extended bottom

-

Reinforced base beating

-

Welding seam polishing

-

Adding reinforcement rings

-

Stamping embossed logo (if applicable)

-

Flattening the top end

-

Bottom end beating and flattening

-

Cleaning and drying

-

Knock pit test

-

Qualified outer shell

-

Assembly: Outer and Inner Shell Connection

-

-

Insert inner shell into outer shell, forming the cup mouth

-

Cup mouth welding

-

Attaching the secondary bottom cover

-

Welding the bottom cover

-

Welding quality inspection

-

Adding desiccant agent via spot welding

-

Vacuum sealing

-

First heat retention test

-

Electrolytic polishing

-

Second heat retention test

-

Final polishing inspection

-

Adding the third bottom cover

-

Spray painting / powder coating (if applicable)

-

Random temperature testing

-

Qualified cup body

-

Graphic decoration (embossing, silkscreen printing, laser engraving, air gas printing, or UV printing)

-

Lid Assembly and Final Testing

-

-

Injection molding of lid components

-

Lid assembly

-

Adding leak-proof seal

-

Screwing lid onto steel cup body

-

Random leakage testing

-

Packaging

-

Finished product storage

-

FAQs About Custom Hydro Flask

Find quick answers to common questions below. Whether you’re exploring our wholesale Hydro vaccum flask or custom design options, this section provides the information you need. Browse the FAQs to save time and get started!

Our vacuum-insulated water bottles are engineered for superior performance. The core benefit is exceptional temperature retention, keeping beverages cold for up to 24 hours or hot for up to 12 hours. This is achieved through a double-wall vacuum insulation technology that creates a barrier against heat transfer. Beyond performance, they are built to be durable, leak-proof, and 100% taste-neutral, making them perfect for daily use, outdoor adventures, or as premium corporate gifts.

We prioritize quality and safety in all our materials:

-

Inner Liner & Outer Wall: Made from high-grade, rust-resistant 304 or 18/8 stainless steel.

-

Insulation Layer: A precision-engineered vacuum seal between the double walls is the key to temperature control.

-

Lid Components: We use food-grade, BPA-free plastics. Options also include stainless steel lids and bamboo tops for a more natural aesthetic.

-

Coating: The exterior can feature a durable, non-toxic paint finish, a powder-coated matte texture, or a polished stainless steel look.

We provide a comprehensive suite of branding techniques to make your bottles uniquely yours:

-

Laser Engraving: Offers a permanent, sophisticated, and tactile finish for logos and text. Ideal for a high-end, durable brand impression.

-

Digital Printing: Allows for full-color, complex artwork, and photorealistic images. Perfect for vibrant designs and patterns.

-

Powder Coating: You can choose from a vast palette of Pantone-matched colors for the bottle’s body to align with your brand identity.

-

Debossing & Silk Screening: Classic methods for crisp and clean logo application on various surfaces.

-

Custom Lid Colors & Accessories: Match the lid color to your brand and add custom straps or carabiners.

Yes, our standard MOQ for custom vacuum bottle orders starts at 300 units. This allows us to maintain high quality and cost-effectiveness. However, we understand the need for samples and smaller test runs. We gladly offer sample orders (1-10 units) for quality verification and marketing purposes before committing to a full production run.

Once your design is finalized and approved, the standard production lead time is 15-25 days. This timeline includes material preparation, manufacturing, quality control checks, and custom packaging. Shipping time will vary based on your location and chosen freight method (air or sea). We provide a detailed schedule upon order confirmation to ensure it aligns with your campaign or launch plan

Absolutely. Our design team is ready to help. We accept common file formats like AI, EPS, or PSD (with layers) for the cleanest results. We recommend a resolution of at least 300 DPI to ensure your branding is sharp and clear. If you only have a JPG or PNG, our team can often vectorize and optimize it for you, subject to a small design fee.

Yes, they are built to last. The 304 stainless steel construction is resistant to dents and corrosion. The vacuum seal is robust and designed to maintain its integrity under normal wear and tear. Many of our models feature a non-slip base and a leak-proof lid seal, making them perfect companions for hiking, commuting, or use in the gym.

Consumer safety is our top priority. All materials that come into contact with beverages are certified food-grade and BPA-free. Our stainless steel is FDA-compliant, and we can provide LFGB and REACH certifications for clients requiring compliance for European and international markets.

We offer a variety of lid styles to suit different needs:

-

Straw Lid: Popular for easy drinking on the go, often with a flip-open spout.

-

Chug Lid: Features a wider opening for a faster flow of liquid.

-

Screw Lid (Loop Cap): A classic, secure option, often with a carrying loop.

-

Press-Button Lid: Convenient for one-handed operation with a built-in lock to prevent leaks.

We specialize in OEM and ODM services. Beyond standard cylinders, we can develop bottles with unique contours, flattened designs for easier carrying, and integrated features like built-in fruit infusers, tea strainers, or handles. Discuss your concept with our sales team, and we can explore the feasibility of bringing your unique product idea to life.