You need packaging that keeps each glass water bottle safe. It must stop glass from hitting other glass. It also needs to prevent problems from bad packaging and shaking during shipping. Good packaging uses inner dividers, tight cartons, and custom foam. These things fill empty spaces and stop bottles from moving. When you ship in bulk, even a few broken bottles can lower your profits. It can also hurt your brand. In 2026, people want packaging that is green and can be changed to fit their needs. This guide, How to Ship Glass Cups in Bulk Without Breakage (Complete B2B Guide 2026), helps importers, wholesalers, and stores. It gives easy steps to balance green choices, cost, and safety.

|

Cause of Breakage |

Description |

|---|---|

|

Glass-on-glass impact |

Happens when items are not kept apart, so they hit each other again and again during shipping. |

|

Improper packaging specifications |

Packaging must fit tightly; gaps bigger than 1-2mm can make bottles shake and hit the sides. |

|

Vibration and shocks |

Shaking and bumps during shipping can slowly damage the bottles over time. |

Key Takeaways

-

Pick strong boxes with two walls to keep glass bottles safe. This helps stop bottles from breaking.

-

Add special foam pieces and dividers inside the box. These keep bottles in place and stop them from touching each other.

-

Wrap every bottle by itself so it does not get scratched or damaged. Use thick foam bags to protect bottles even more.

-

Use packaging that is good for the environment. This helps your business be green and makes customers happy.

-

Check everything carefully before shipping. This makes sure bottles are good and lowers the chance of returns from damage.

Why Shipping Glassware in Bulk Is High-Risk

Fragility and Weight Issues

Shipping glassware in bulk is not easy. Glass bottles are heavier than plastic bottles. For example, a 2 fl. oz glass bottle weighs .177 lbs. A plastic bottle of the same size weighs only .023 lbs. This makes shipments much heavier. You pay more for shipping because of the weight. You also have to move heavier boxes. Glassware can break easily if it is not handled carefully. Even small bumps can crack or break the bottles. When you use IFUN customizedwaterbottles, you need to protect each bottle. Glass is fragile, so good packaging is very important.

-

Glassware is heavier than plastic bottles.

-

Heavy shipments cost more to ship.

-

Glass breaks easily if handled roughly.

-

Bulk shipping needs extra care for each bottle.

Common Transit Breakage Causes

It is important to know why glassware breaks during shipping. The table below lists the main causes and explains them.

|

Cause of Breakage |

Description |

|---|---|

|

Physical shock and collision |

Small bumps, drops, or shaking can break or shatter bottles. |

|

Uneven packaging |

Bad weight balance makes bottles move and hit each other, causing more breakage. |

|

Thinness and design of glass bottles |

Bottles that are thin and light cost less but break more easily during shipping. |

|

Temperature change |

Sudden changes in temperature can crack bottles, especially when flying. |

|

Vibration |

Constant shaking from transport can make tiny cracks in the glass. |

Industry Damage Rates

You should check damage rates in the industry to see your risk. Many glassware shipments have breakage rates between 2% and 8%. High breakage means you lose money and customers get upset. When you ship IFUN customizedwaterbottles, try to keep the damage rate as low as possible. Careful packing and handling help protect your bottles and keep your business strong.

How to Ship Glass Cups in Bulk Without Breakage (Complete B2B Guide 2026)

Inner Dividers and Partition Design

Start by picking the right inner dividers for shipping glassware. Cardboard box divider inserts are good for glass water bottles. These dividers cushion each bottle and keep them apart. You can change them to fit different box sizes. This helps cut down on packaging waste. The design lets you fold them flat for easy storage. When using IFUN customizedwaterbottles, you must keep every bottle still. Even tiny movements can cause cracks and breakage. Good partition designs stop bottles from moving inside the box. This step is very important for shipping glass cups in bulk without breakage.

-

Cardboard dividers keep bottles apart and stop glass-on-glass contact.

-

Custom partitions fit tightly and fill empty spaces.

-

Dividers help you use eco-friendly materials for sustainability.

Always check that your packaging keeps bottles from moving. If bottles move, they can break. Partition designs that stop movement give the best protection for glassware.

Custom Foam and Modular Packaging

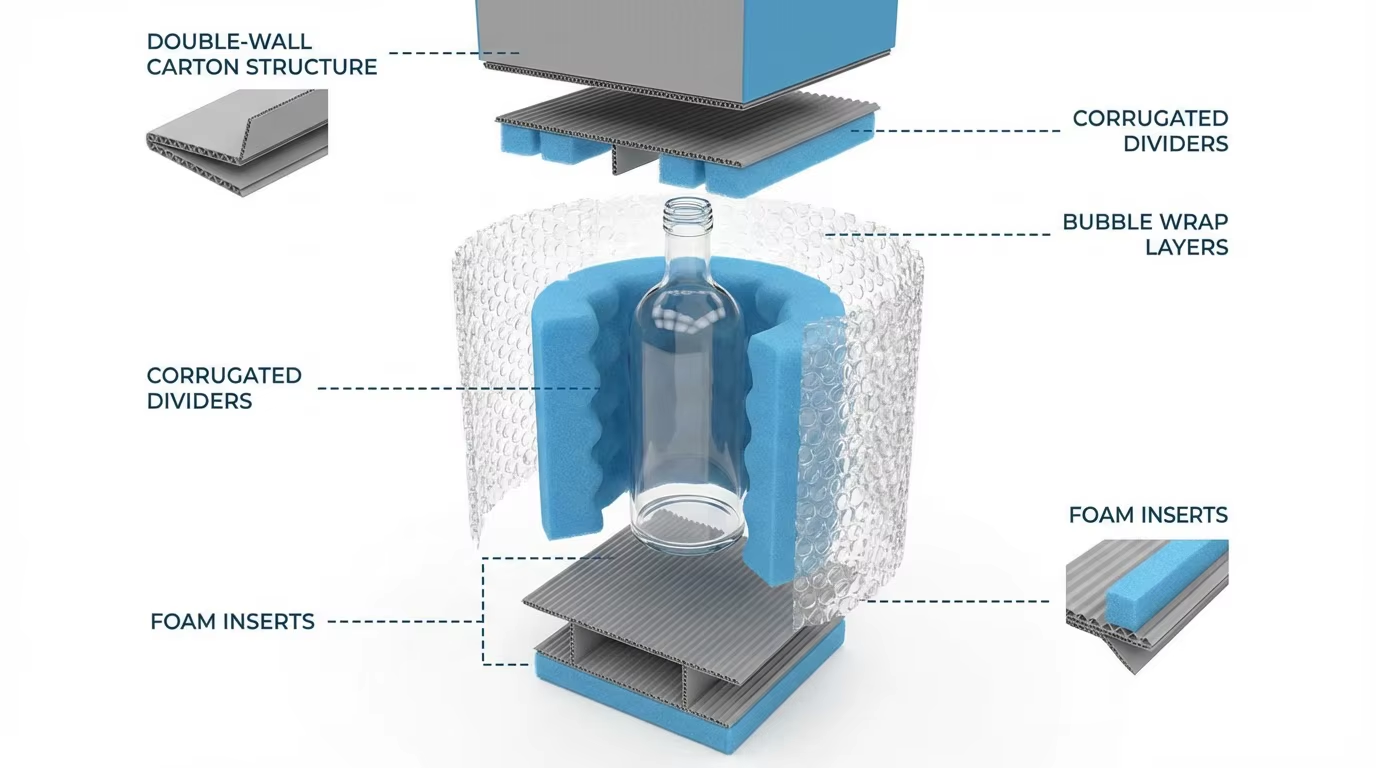

Modern packaging uses custom foam and modular systems to protect glassware. You can pick retention inserts, suspension packaging, or custom foam cushioning. These methods hold each bottle in place and absorb shocks during shipping.

Custom foam and modular packaging, like retention inserts, suspension packaging, and custom foam cushioning, give better protection for glass water bottles during shipping than old packaging methods. These new solutions are made to stop movement and impacts, so bottles break less often. Old methods use weaker materials that do not hold bottles well, which leads to more damage.

Custom foam gives better protection than old-style packaging. Modular packaging lets you change the layout for different bottle shapes and sizes. This flexibility is important for shipping glass cups in bulk without breakage. You can impress B2B buyers with smart cushioning and neat packaging. IFUN customizedwaterbottles stay safer with these advanced methods, which help lower breakage rates and keep your brand strong.

Proper Wrapping Techniques

Wrapping each glass bottle is needed for safe bulk shipping. Bag each bottle to stop friction damage. Foam dividers give extra cushioning. You need packaging that saves money and keeps bottles safe. Wrapping glassware protects it from scratches and breaking.

-

Wrap bottles one by one with PE bags to stop scratches.

-

Use thicker foam bags for more protection if needed.

-

Kraft paper dividers keep bottles apart inside shipping boxes.

The best ways to wrap glass bottles use foam inserts, bubble wrap, and air pillows. These materials cushion each bottle and stop them from hitting each other. Proper box sizing makes sure bottles do not move during shipping. Secure bottles inside the package with stretch wrap or corrugated trays. Layering and spreading weight lowers pressure damage.

|

Best Practice |

Description |

|---|---|

|

Use Foam Inserts and Dividers |

Foam inserts cushion and separate bottles, stopping them from hitting each other during shipping. |

|

Bubble Wrap or Air Pillows |

These materials make a soft layer around each bottle, stopping scratches and breakage. |

|

Proper Box Sizing |

Makes sure bottles do not move during shipping, lowering the risk of damage. |

|

Secure Bottles Inside the Package |

Use stretch wrap or corrugated trays to keep bottles from moving inside the box. |

|

Layering and Weight Distribution |

Spreading weight evenly and layering bottles with padding lowers pressure damage during shipping. |

Follow these steps for shipping glass cups in bulk without breakage. You will see fewer broken bottles and happier B2B customers. IFUN customizedwaterbottles stay safe and look good when you use the right packaging and protection.

Glassware Packaging Trends for 2026

Sustainable Materials and Regulations

Brands are changing how they package glassware. They want to use materials that are better for the planet. Most packaging is now recyclable, reusable, or biodegradable. You need to pick packaging that is good for the environment and makes customers happy. There are new rules called Extended Producer Responsibility (EPR) laws. These laws say you must use packaging that helps with recycling and is eco-friendly. Following these rules keeps your business safe and your reputation strong. IFUN customizedwaterbottles use packaging that meets these rules. This helps you stay ahead of other companies. Using sustainable packaging means you make less waste. It also shows you care about shipping responsibly.

Tip: Always check if your packaging follows local recycling rules. This keeps your brand safe and protects your glassware during shipping.

Customization and Personalization

You can now make your glassware packaging special. Digital printing lets you design each batch in a new way. You can use packaging to show off your brand. Add logos, messages, or pictures for special events. AI helps you make different packaging for different places or groups. This makes B2B buyers notice your products. IFUN customizedwaterbottles use these new ideas. This helps people remember your brand.

|

Trend |

Description |

|---|---|

|

Digital Printing Technology |

You can make small batches fast and cheap. This lets you create packaging just for your customers. |

|

You can make special designs for big groups. You can add names or messages for events or certain people. |

|

|

Cost-Effective Customization |

Digital printing lets you make cool packaging. This turns your packaging into a way to market your brand. |

Innovative Cushioning Designs

You need packaging that keeps glassware from breaking. New designs use foam, air pillows, and special inserts. These keep bottles safe and stop them from moving. You can pick packaging that fits each bottle shape. This helps stop damage and makes shipping better. Modular packaging can change to fit different bottle sizes. This saves time and makes shipping easier. You get fewer broken bottles and happier customers. IFUN customizedwaterbottles use these smart packaging ideas. Your products arrive safe and look great. You meet your business goals and help the planet at the same time.

Note: Modular packaging lets you use the same inserts for different products. This saves money and makes less waste.

Master Carton Engineering

Ply Thickness and Carton Strength

Strong cartons are needed for shipping glass water bottles. Ply thickness shows how much weight a carton can hold. Most B2B shipments use cartons with three or five layers. Thicker cartons protect IFUN customizedwaterbottles from crushing and outside force. Always check the ply rating before picking packaging. Strong cartons keep bottles safe when stacked and moved. Using the right carton strength lowers breakage risk.

Double-Walled Corrugated Boxes

Double-walled corrugated boxes protect better than single-walled boxes. They have two layers of fluting and three liners. This makes packaging stronger and safer for fragile glassware. The table below shows the benefits:

|

Advantage |

Double-Walled Boxes |

Single-Walled Boxes |

|---|---|---|

|

Strength |

More strength because of extra layers |

Less strength |

|

Protection against damage |

Better protection from crushing and holes |

Less protection |

|

Suitability for fragile items |

Great for fragile items like glassware |

Not good for fragile items |

Double-walled boxes help stop damage from drops and heavy loads. IFUN customizedwaterbottles stay safer with this packaging. You also meet B2B buyer needs for safe delivery.

Compression and Drop Test Standards

You must follow industry rules to check your packaging. Compression and drop tests show how well cartons protect glass bottles. There are different tests you can use:

|

Test Type |

Description |

|---|---|

|

Impact/Drop Tests |

Copy real handling; includes single-bottle and filled-bottle drop tests. |

|

Internal Pressure Test |

Checks if bottles can handle pressure from fizzy or flavored water. |

|

Vertical Load Test |

Makes sure stacked pallets do not crush bottles. |

|

Thermal-Shock Resistance Test |

Uses ISO 7459:2004 rules for thermal shock strength. |

Run these tests before shipping IFUN customizedwaterbottles. You make sure packaging can handle shocks, stacking, and temperature changes. This lowers breakage and keeps B2B customers happy.

Palletization and Container Loading

When to Use Pallets

Use pallets when you ship lots of glass water bottles. Pallets help move heavy boxes with forklifts. They make shipments neat and save time. Stacking IFUN customizedwaterbottles on pallets lowers breakage risk. Pallets keep boxes dry and off the ground. Loading and unloading is faster with pallets. For big B2B orders, pallets work best for more than 500 bottles. They are also good for standard 20-foot or 40-foot containers.

Tip: Make sure your pallet size fits your container and cartons. This helps you use space well and not waste room.

Container Capacity Comparison

Pick the right container for your shipment and bottle type. Glass water bottles come in many shapes and sizes. The table below shows common choices and their uses:

|

Bottle Type |

Size Options (ml) |

Capacity Description |

|---|---|---|

|

Sparkling Water Glass Bottles |

250, 330, 500 |

Good for fizzy drinks, strong glass. |

|

32 oz Clear Glass Boston Round |

946 |

Classic shape, holds many liquids. |

|

Common Sizes of Glass Water Bottles |

250, 330, 500, 750, 1000 |

Tall/slim or short/wide shapes for different needs. |

A 20-foot container holds about 10–12 pallets of IFUN customizedwaterbottles. A 40-foot container fits up to 24 pallets. Plan your order by bottle type and cartons per pallet. This saves money and stops overloading.

Load Stability Techniques

Keep your load steady to stop bottles from breaking. Use these ways to protect glass water bottles:

-

Pack bottles in strong cartons or blister packs before stacking.

-

Put foam or cardboard between layers and bubble wrap between bottles.

-

Stack no more than five layers high (max height 1.8 meters).

-

Secure pallets with stretch film and strapping bands.

-

Wrap each IFUN customizedwaterbottle in bubble wrap and seal with tape.

-

Place bottles upright with dividers and fill gaps with packing peanuts or foam sleeves.

Note: Stable loads lower damage risk and help you meet B2B delivery rules. Always check pallets do not move during loading or unloading.

Follow these steps to keep IFUN customizedwaterbottles safe and make customers happy.

Freight Options for Glassware Shipping

When you choose how to move glass water bottles in bulk, you must compare sea and air freight. Each method has its own cost, speed, and risk of damage. Picking the right option helps you protect your IFUN customizedwaterbottles and control your budget.

Sea vs Air Freight Cost

Sea freight is the most common choice for bulk shipping. You pay less per unit because ships carry large loads. This method works well for big orders of IFUN customizedwaterbottles. Air freight costs much more. You pay a premium for speed and convenience. Most B2B buyers use air freight only for urgent or high-value shipments. If you want to save money, sea freight is the better option for most glassware shipping needs.

Damage Rate Comparison

You must think about the risk of breakage. Sea freight often has higher damage rates. Ships move for weeks, and containers face more vibration and stacking pressure. Air freight moves faster and handles cargo with more care. You see fewer broken bottles with air freight, but you pay more for this safety. To lower damage, always use strong packaging and follow best practices for shipping IFUN customizedwaterbottles.

Tip: Use double-walled cartons and inner dividers for both sea and air freight. This keeps your glass bottles safe during long trips.

Transit Time Differences

Transit time matters for your business. Air freight delivers your glassware quickly. Sea freight takes much longer. The table below shows the average transit times for each method:

|

Freight Mode |

Average Transit Time |

|---|---|

|

Sea Freight |

20-60 days |

|

Air Freight |

1-10 days |

If you need IFUN customizedwaterbottles fast, choose air freight. For regular restocking or large orders, sea freight gives you better value. Always plan your shipping schedule based on your sales needs and customer deadlines.

Factory Quality Control for Low Breakage

Pre-Shipment Inspection

You must check each batch before shipping. Pre-shipment inspection helps you find problems early. You look for cracks, chips, or coating flaws. You test bottles for leaks and insulation. You use random sampling to check all IFUN customizedwaterbottles meet your standards. You want a 98-99% pass rate. This step protects your business from returns and unhappy customers.

|

Quality Control Measure |

Description |

|---|---|

|

Pre-production checks |

Two rounds of sample approval to make sure quality is good before mass production. |

|

Pre-shipment checks |

Testing bottles before shipping to catch any issues early. |

|

Random sampling |

Picking bottles randomly from batches to check quality across all products. |

|

Cross-hatch test |

A test to check how strong the bottle’s coating is. |

|

Standard tests |

Includes insulation, leak tests, and upside-down leak tests to check bottle strength. |

|

Pass rate target |

Aiming for a 98-99% pass rate to lower breakage during shipping. |

|

Using machines to find flaws that people might miss, lowering mistakes. |

Double QC Process

You need two quality checks to keep glassware safe. First, you approve samples before making lots of bottles. Second, you check finished bottles before packing. Automated bottle inspection helps you find flaws people miss. Machines check for cracks, weak spots, and coating issues. This process makes quality better and lowers breakage for IFUN customizedwaterbottles.

Smart bottle inspection fixes this problem. Using automated bottle quality control stops costly mistakes and waste. It finds flaws people do not see.

Drop Test Procedures

You must test glassware for strength and toughness. Drop tests show how bottles handle shocks during shipping. You drop bottles from different heights and check for cracks or breaks. You also run internal pressure resistance, vertical load strength, impact resistance, and abrasion resistance tests. These tests make sure IFUN customizedwaterbottles can survive shipping and handling.

-

Internal Pressure Resistance (Hydrostatic Test)

-

Vertical Load/Top Load Strength

-

Impact Resistance Testing

-

Abrasion Resistance

You use these tests to keep quality high and protect your brand.

Damage Compensation Policies

You need clear damage compensation policies for B2B buyers. If glassware breaks during shipping, you offer replacements or refunds. You track breakage rates and change your quality control steps. You work with your factory to improve packaging and inspection. IFUN customizedwaterbottles come with strong support and fair policies. This builds trust and keeps your business relationships strong.

Note: Good compensation policies show you care about quality and customer happiness. You protect your reputation and encourage repeat orders.

Case Study: US Retail Chain Bulk Order

Order Size and Packaging Solution

You handled a big order for a US retail chain. The order had 30,000 IFUN customizedwaterbottles made from premium glassware. The client wanted less breakage and eco-friendly packaging. You picked double-walled cartons with five-ply strength. Each carton held 24 bottles with custom cardboard dividers. Modular foam inserts gave extra shock protection. This packaging met the retailer’s green needs and kept bottles safe.

Note: Using recyclable materials in glassware packaging helps you meet business and environmental standards.

Loading Strategy

You planned the loading to keep bottles safe and make work easy. Cartons were stacked on heat-treated wooden pallets. Each pallet carried 40 cartons and stayed under 1.7 meters tall. You wrapped pallets with stretch film and used corner protectors. Pallets stood upright in a 40-foot container with no empty spaces. Air pillows went between the last row and the container wall. This kept glassware stable during shipping.

Loading Checklist:

-

Use strong pallets and stack cartons evenly

-

Secure with stretch film and corner guards

-

Fill gaps with air pillows for extra stability

Final Damage Rate

After arrival, you checked the shipment with the retail chain’s team. Out of 30,000 bottles, only 18 had small chips or cracks. This made a damage rate of just 0.06%. The client liked your glassware shipping plan and asked for another order. Your careful planning and advanced packaging for IFUN customizedwaterbottles helped you get great results.

|

Metric |

Value |

|---|---|

|

Total Bottles Shipped |

30,000 |

|

Bottles Damaged |

18 |

|

Damage Rate |

0.06% |

Success in glassware shipping comes from strong packaging, smart loading, and quality control.

Bulk Shipping Cost Breakdown

Packaging Cost Per Unit

You should know how much packaging costs for each IFUN customizedwaterbottles unit. Good packaging keeps glass bottles from breaking. The price changes based on the materials you pick. Custom foam inserts, inner dividers, and double-walled cartons cost more than plain boxes. These choices help stop breakage and save money over time. Most B2B buyers pay $0.30 to $0.80 per bottle for strong packaging. If you want eco-friendly packaging, it might cost a bit more. Always compare packaging cost to the value of your glass water bottles.

Pallet and Container Costs

Pallet and container costs are a big part of shipping costs. Glass water bottles are heavy and break easily. You need strong pallets and tough containers. Good packaging, like strong dividers and shrink-wrap, keeps bottles safe when moving. Freight costs for heavy loads can change with world demand. You should also know shipping terms like FOB and DDP. These terms decide who pays for shipping and customs. Here are some things to remember: Pallet costs include the pallet price and the work to load it. Container costs depend on size and shipping route. Good packaging lowers damage and extra fees. Shrink-wrap and dividers cost more but protect your IFUN customizedwaterbottles. Freight rates can go up during busy times or world events.

Estimated Landed Cost

You need to figure out the landed cost to see your real profit. Landed cost means packaging, pallet and container fees, freight, insurance, customs, and delivery to your warehouse. For IFUN customizedwaterbottles, packaging and freight are most of the landed cost. If you use better packaging, you pay more at first but lose less to breakage. Always ask your supplier for a full cost list. This helps you set the right price for your B2B customers and avoid surprises.

Tip: Check your landed cost for every shipment. This helps your business make money and keeps your customers happy.

Why Choose a Professional OEM Glass Bottle Factory

Customization Capabilities

You want bottles that fit your brand. IFUN customizedwaterbottles lets you pick shapes, sizes, and colors. You can add your logo or special designs. The factory uses new machines to print, engrave, or label bottles. This makes your bottles unique and helps you meet your clients’ needs.

Stable Production and Delivery

You need your orders to arrive on time. IFUN customizedwaterbottles follows strict schedules and checks quality. The factory handles big orders without delays. You get steady supply, even when it is busy. Reliable production helps you plan sales and never run out of stock.

Export-Standard Packaging

Safe shipping starts with strong packaging. IFUN customizedwaterbottles uses export-standard packaging for every order. The factory picks double-walled cartons, custom foam inserts, and inner dividers. These protect bottles from shocks and pressure. You get your products with little breakage. The packaging meets shipping rules, so your goods clear customs easily.

Note: Export-standard packaging lowers damage and saves money on replacements.

Long-Term B2B Cooperation

You need a partner who helps your business grow. IFUN customizedwaterbottles builds long-lasting relationships with B2B clients. The factory offers flexible order sizes and quick help. You get support with packaging, shipping, and after-sales service. This partnership helps your brand grow and keeps your customers happy.

Call to Action

Want better glass water bottles? Contact IFUN customizedwaterbottles for a free sample or custom loading plan. See how professional OEM service makes a difference. Start safer, smarter, and more reliable glassware shipping today.

You can keep glass bottles from breaking if you follow these steps: Pick cartons that are strong and use double-walled boxes. Add custom foam, inner dividers, and modular packaging to protect bottles. Wrap bottles the right way and stack them on pallets carefully. Check quality and do drop tests to make sure bottles are safe.

IFUN customizedwaterbottles uses smart packaging and green solutions to help your business do well. Ask us for samples or a special loading plan. 🚚

FAQ

How do you prevent glass water bottles from breaking during shipping?

You use strong boxes with two walls. Custom foam inserts and inner dividers help keep bottles safe. IFUN customizedwaterbottles stay protected with these steps. You wrap each bottle and stack boxes on pallets. This gives extra safety.

What is the best packaging material for glass water bottles?

Custom foam, cardboard dividers, and double-walled boxes are best. These materials protect IFUN customizedwaterbottles from bumps and pressure. You get fewer broken bottles and your products look good.

Can you use eco-friendly packaging for bulk glass shipments?

Yes, you can pick recyclable or biodegradable materials. IFUN customizedwaterbottles has green packaging choices that follow new rules. You help the planet and show your brand cares about being eco-friendly.

How do you handle damage claims for B2B orders?

You report any damage right away. IFUN customizedwaterbottles gives replacements or refunds as agreed. You get help for every order. This builds trust and keeps your business strong.

What is the typical lead time for bulk orders?

You usually wait 20 to 45 days for production and shipping. IFUN customizedwaterbottles gives you a clear schedule before you order. You can plan your inventory and sales with confidence.