Contact Us: +86 13855215327 | info@customizedwaterbottles.com

Stainless Steel Water Bottle OEM / ODM Manufacturing

At Anhui IFUN, we specialize in high-quality OEM/ODM manufacturing of stainless steel drinkware, offering tailored solutions to bring your brand vision to life. Our dedicated R&D team launches 50+ innovative products annually, including:

- Vacuum-insulated water bottles & tumblers

- Travel mugs, coffee pots, & food jars

- Beer pints & growlers

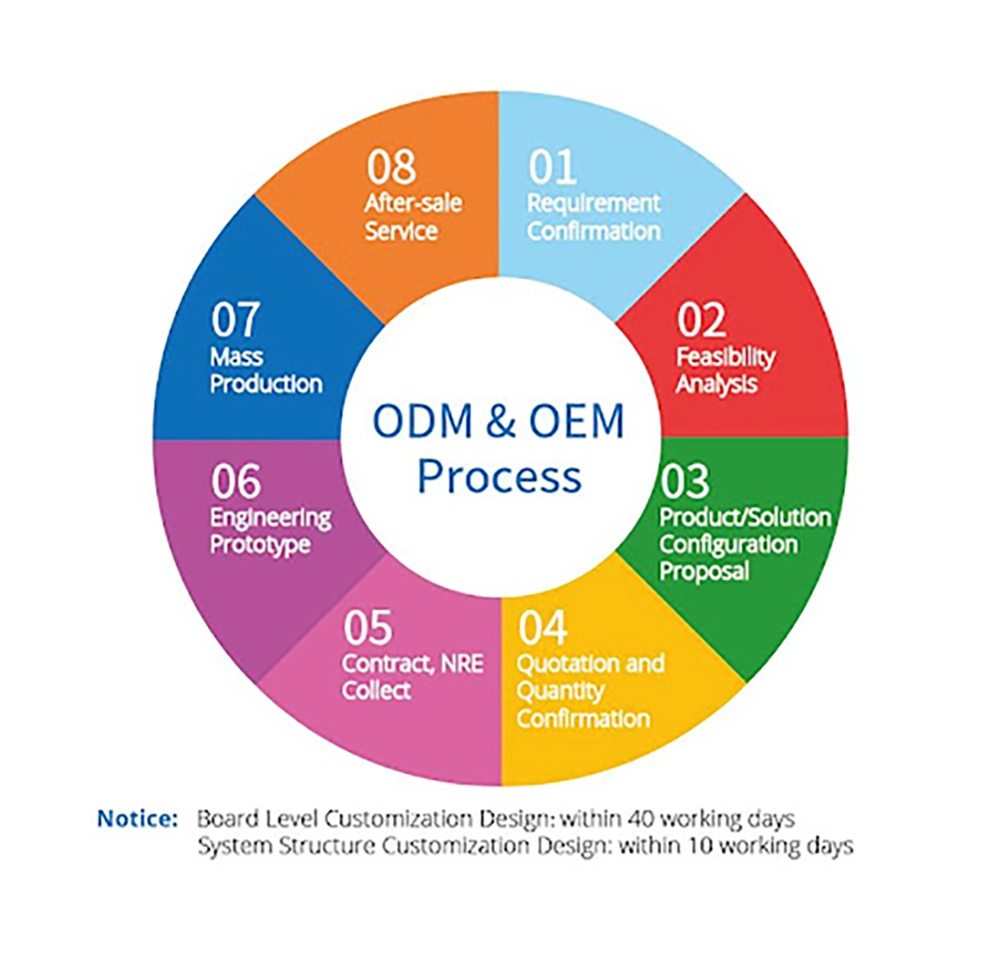

OEM/ODM Service – Drinkware Manufacturing

1. OEM Service – Built to Your Specs

Submit your product requirements (capacity, dimensions, materials, colors, surface treatments, etc.), along with any technical drawings. We’ll provide a competitive quote and free samples for approval.

Full Customization: Molding, decoration, packaging—we bring your vision to life.

Precision Manufacturing: Strict adherence to your specifications for consistent quality.

2. ODM Service – Choose & Customize

Browse our catalog on www.customizedwaterbottles.com, select your preferred models, and share the item numbers. We’ll handle the rest:

- Free samples & quotes

- Logo/packaging customization

- Low MOQ support

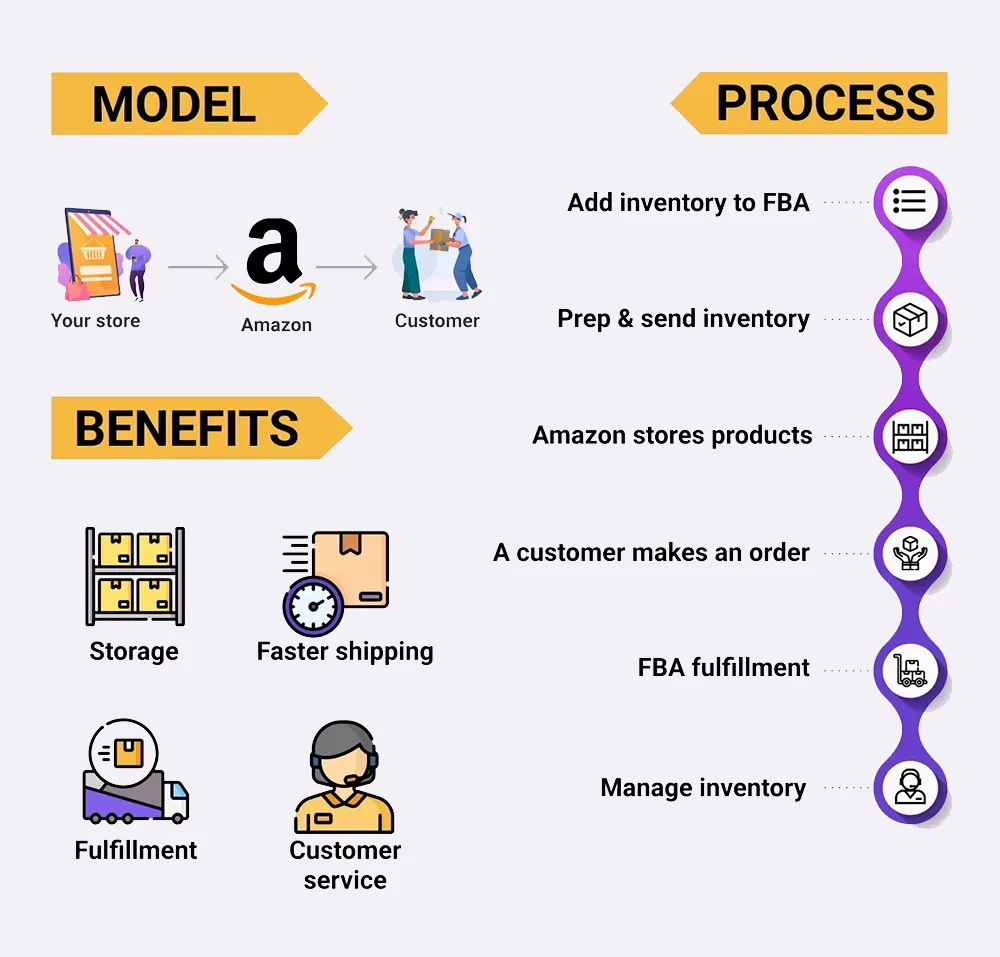

Full Service For Amazon FBA Seller

Anhui IFUN is a trusted partner for Amazon sellers, offering end-to-end FBA solutions:

1. Compliance & Logistics

FNSKU Stickers/Labels: Applied to products or printed directly on packaging.

Direct Shipping: Seamless delivery to Amazon fulfillment centers.

Regulatory Checks: Ensure your products meet destination-country standards.

2. Branding & Sales Support

Private Labeling: Custom logo & packaging design services.

High-Quality Product Photos: Ready-for-Amazon images for listings.

3. Proactive Quality Improvement

Our team monitors customer reviews weekly (Amazon + other platforms), analyzes feedback, and implements improvements for future orders—keeping your brand competitive.

Why Choose Anhui IFUN?

15+

Years of OEM/ODM expertise

50+

New Designs annually

1-Stop

FBA Support from production to warehouse

Anhui IFUN OEM Water Bottle Production Process

Shape Forming

Cutting

Welding

Polishing

Electrolysis Cleaning Program

Powder Coating

5D Printing

Laser Etching

Inspection

Assembly

Uncompromising Quality

At Anhui IFUN, quality is non-negotiable. Our rigorous quality control ensures every product meets the highest standards before shipment. From material selection to final inspection, we guarantee durability, functionality, and premium craftsmanship in every item.

Fast & Reliable Production

We continuously expand production capacity and streamline processes to minimize lead times. Through optimized supply chains and efficient planning, we ensure:

- Faster material sourcing

- Smoother production flow

- On-time delivery

Low MOQ – Start Small, Grow Big

Designed to empower startups and small businesses, our low minimum order quantities (MOQ) reduce upfront risks. Test the market safely, scale confidently, and invest with peace of mind.

Strength of Our Services

Rapid Response Guarantee

- Dedicated 24/7 customer support

- All inquiries and complaints addressed within 24 hours

- Proactive communication at every project stage

Seamless Global Communication

- Native-level English communication

- Precise technical & business correspondence

- Multilingual support available (Spanish/French/German/Japanese etc.)

- Dedicated project managers for clear requirement understanding

Industry-Leading Expertise

- 15+ years specializing in vacuum insulated products

- Decades of OEM/ODM manufacturing experience

- Proven track record with global brands

Tooling Fabrication & Sample Approval

Tooling Lead Time:

Approximately 2~5 weeks.

Sampling Process:

3D Prototype: Receive a printed prototype for initial design validation.

T1/T2 Samples:

Receive initial production samples from the new molds for final approval of form, fit, and function.