You reach for your favorite mug or water bottle every day, trusting it to keep your drinks safe. Many people overlook the risks that come with Common Drinkware Issues, which can affect your health and safety. Small changes in how you choose and care for your cups and bottles can help you avoid harmful toxins and other problems related to Common Drinkware Issues.

Tip: Start by checking your drinkware for damage or odd smells. This simple habit helps you spot Common Drinkware Issues early, supporting healthier hydration and peace of mind.

Why Drinkware Issues Matter for Amazon Sellers

High Return Rates in the Drinkware Category

Selling drinkware on Amazon is hard. Many customers send items back. This happens for different reasons.

-

Wine glasses can snap at the stem if packed badly.

-

Stanley mugs were recalled because lids could burn people.

These problems upset buyers and cost you money. You need to watch for Common Drinkware Issues. This helps keep returns low and customers happy.

How Product Defects Impact Reviews and Ranking

Defects hurt your reputation fast. Buyers get broken items and leave bad reviews. Bad reviews lower your seller rating. Your ranking on Amazon drops. You should check Order Defect Rate (ODR). A high ODR makes your products harder to find. Good ratings help you sell more. Fixing defects and reviews keeps you ahead.

Tip: Reply to bad reviews fast. Show buyers you care and want to help.

The Importance of QC and Reliable OEM Partners

You can lower defects by picking good OEM partners. These partners use strong quality control. They test samples and look for problems early. They use design libraries to avoid mold mistakes. The table below shows how good partners help:

|

Evidence Point |

Descrição |

|---|---|

|

Consistent Quality Control |

Good manufacturers fix defects early in production. |

|

Prototyping and Testing |

They test samples to find issues before making many items. |

|

Design Optimization |

They use smart designs to stop mold problems. |

Choosing good partners and checking quality protects your brand. It also keeps your customers safe.

Problem 1 – Leaking Lids

Common Causes

Leaking lids can frustrate you and damage your trust in a product. You may notice spills when you carry your bottle or mug in a bag. Several factors contribute to this issue. You should watch for these common causes:

-

Improper lid closure often leads to leaks and spills.

-

Design flaws in the lid can prevent a snug fit, allowing liquid to escape.

-

Manufacturing defects may create gaps or cracks in the lid.

-

Wear over time can degrade seals, making leaks more likely.

You can spot these problems early by checking your drinkware before each use. Many Common Drinkware Issues start with small defects that grow worse over time.

How to Fix

You can fix a leaking lid by following a few simple steps. First, inspect the silicone ring or gasket inside the lid. If you see cracks or wear, replace the ring with a new one. Clean the lid and ring with warm water and mild soap to remove debris. Make sure you close the lid tightly every time you use it. If the lid still leaks, contact the manufacturer for a replacement part or warranty support.

Tip: Always test your lid with water before using it for hot drinks. This helps you avoid burns and messy spills.

How to Prevent for FBA Orders

Larger silicone ring size tolerance

When you order drinkware for Fulfillment by Amazon (FBA), you should request larger silicone ring size tolerance from your supplier. This ensures the ring fits snugly and reduces the risk of leaks. Ask your supplier to measure and verify the ring size for every batch.

Leak-proof pressure testing

You can require leak-proof pressure testing for every shipment. This test checks each lid for leaks before products reach customers. Reliable suppliers will perform this test and share results with you. This step helps you avoid returns and keeps your brand reputation strong.

Problem 2 – Paint Peeling or Scratching

Causes

Paint can peel or scratch after a few uses. This often happens because of how the surface is finished. Some ways make paint weaker. Here are the main causes:

-

Liquid spray painting gives many looks but wears off fast.

-

Spraying can fade, peel, or scratch as time passes.

-

Rough use or washing a lot makes damage happen sooner.

-

Sunlight or strong chemicals can make paint weaker.

Powder coating is a better choice. It sticks well to stainless steel. It does not scratch or chip easily. You will see less peeling with powder-coated drinkware, even if you use it every day.

Fixes

You can fix small scratches with a soft cloth. Rub the area gently. If paint peels, stop using the drinkware. Replace it or call the maker. You might get a warranty if it happens soon after buying. If you see paint flakes inside, do not use it. Paint flakes can mean bigger Common Drinkware Issues. These may hurt your health.

Tip: Always look for paint damage before you use your drinkware. This helps you avoid eating paint flakes.

Preventive Measures

Pick drinkware with powder coating to stop peeling or scratching. This finish lasts longer and resists damage. Ask your supplier about how they finish the product. Look for items that meet paint adhesion standards.

Adhesion test (Cross-cut test)

Manufacturers use the cross-cut test to check paint sticking. They cut small lines in the paint and see if it peels. ASTM International has rules for glass, but not for stainless steel or plastic drinkware. You can ask your supplier for this test. It helps make sure your products are high quality.

|

Manufacturing Process |

Issues Associated with Paint Peeling/Scratching |

|---|---|

|

Spraying |

Can fade, peel, or scratch over time. |

|

Liquid Spray Painting |

Gives many finishes but wears out fast. |

|

Powder Coating |

Resists scratches and chips; does not peel with normal use. |

Note: Powder coating sticks well to stainless steel. It does not peel with normal use. This makes it a good choice for drinkware that gets washed a lot or sits in sunlight.

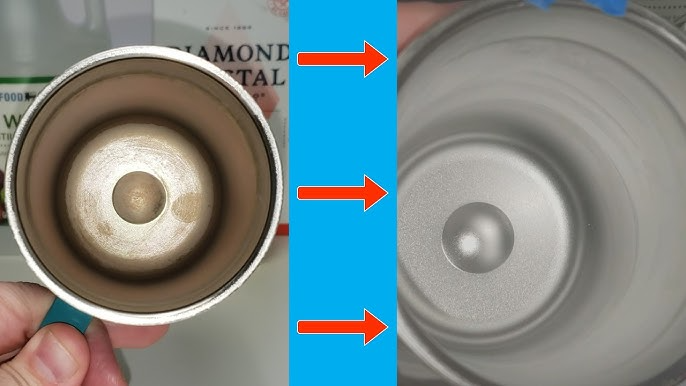

Problem 3 – Rust or Metallic Smell

Causes

Sometimes, your drinkware can smell like metal or get rusty. This happens when stainless steel touches water, heat, or sour drinks many times. Rust and tarnish can show up fast, especially if you live near the ocean or use bottles outside. Rust can make your drinks taste bad and give them a strange flavor.

-

Stainless steel rusts when it gets wet and hot.

-

Sour drinks, like juice or soda, make rust happen faster.

-

Salty air near the coast makes rust more likely.

If you notice these problems, you have Common Drinkware Issues. These can change how your drinks taste and affect safety.

Fix

To clean small rust spots, use baking soda and water to make a paste. Rub the rusty part gently with a soft cloth. Rinse well and dry your drinkware right away. If the metallic smell stays, soak your bottle in vinegar and water for a few hours. Always dry your bottles and mugs after washing. If rust keeps coming back, buy a better stainless steel bottle.

Tip: Do not leave drinks in your bottle overnight. This helps stop rust and keeps your drinkware fresh.

Prevention for OEM Buyers

Picking the right stainless steel stops rust and bad smells. Ask your supplier to check the material before making your products. Two common types are 304 and 316 stainless steel. 304 stainless steel does not rust easily and works for most drinks. 316 stainless steel has molybdenum, which helps fight acids and salt. This makes 316 good for tough places or near the ocean.

|

Stainless Steel Grade |

Corrosion Resistance |

Caraterísticas principais |

|---|---|---|

|

304 |

Good |

Food grade, resists common beverages |

|

316 |

Excellent |

Enhanced with molybdenum, resists chlorides and harsh environments |

Material test (304/316 verification)

Ask your maker to do a material test to check the stainless steel type. This makes sure your drinkware is safe and less likely to rust. Good suppliers give you test reports for every batch. You can use these reports to check quality and avoid Common Drinkware Issues before selling.

Problem 4 – Dents or Deformation

Causes

Your drinkware can get dents from shipping or daily use. Damage often happens when items are moved or stored. Fast machines in factories can cause more dents. Weak boxes or bad packing make things worse. Watch out for these common causes:

-

Thin boxes can break if stacked too high.

-

Sharp corners can get bent at sorting centers.

-

Workers may drop bottles or mugs by mistake.

-

Bad pallets can shift and crush items.

-

Untrained workers may stack things the wrong way.

Drinkware made with soft metals, like aluminum, dents easily. Dents are not just about looks. They can cause leaks or make the drinkware unsafe. Dents and deformation are Common Drinkware Issues. They hurt quality and customer trust.

Fix

You cannot always fix dents or bent drinkware. If you see a dent, check if it leaks. Small dents may be okay, but big ones can break the bottle. If you see cracks or leaks, stop using it. Contact the seller for a new one if it arrives damaged. Most brands give a warranty for shipping damage.

Tip: Check your new drinkware when it arrives. Report dents or bent parts right away for a fast fix.

Prevention for Amazon Sellers

You can stop dents by using better packing and careful handling. Use strong double-wall boxes for more protection. Put bubble wrap or foam inside boxes to stop shocks. Make sure the weight is spread out in each box. Train your team to handle drinkware gently.

Drop-test requirements

Set drop-test rules for your suppliers. A drop test checks if the box keeps drinkware safe when dropped. Ask suppliers to use strong boxes and extra packing. The table below shows ways to lower damage:

|

Method |

Descrição |

|---|---|

|

Over Packing Techniques |

Put the carton in a bigger box and fill gaps with soft materials to stop shaking. |

|

Limit Empty Space |

Make sure items fit tight so they do not move or break. |

|

Use Sturdy Boxes |

Pick tough boxes that can handle moving and weather. |

|

Expandable Foam |

Use foam that grows to fill the box and protect the drinkware. |

You can also use air pillows, loose peanuts, or foam for more safety. These steps help you avoid Common Drinkware Issues and keep buyers happy.

Problem 5 – Straw or Spout Malfunctions

Causes

Problems with straws and spouts can mess up your day. You might see leaks or have trouble drinking. Many things can cause these issues:

-

The sealing ring can get weak or move, which makes leaks.

-

Changes in temperature can push liquid out of the straw.

-

If the straw is not lined up right or gets worn, it can leak.

-

Bags or other things pressing on your bottle can make liquid spill.

-

Over time, the straw and spout can get tired and stop working well.

Check your drinkware often for these Common Drinkware Issues. Finding problems early helps you keep your drinks safe.

Fix

To fix straw or spout problems, look at each part closely. Take out the straw and wash it with warm water and soap. Look at the sealing ring for cracks or damage. If you see problems, get new rings or straws from the maker. Make sure the straw is lined up before you close the lid. If leaks keep happening, ask customer support for help. Always test your drinkware with water before using hot or sticky drinks.

Tip: Keep your bottles standing up and do not squeeze them in tight places. This helps stop leaks from pressure.

Prevention

Picking the best straw material makes your drinkware last longer. Look for bottles with strong and smart straws. Makers test how hard straws are to make sure they work well. The table below shows how different straw materials compare:

|

Material |

Safety Features |

Durability Features |

|---|---|---|

|

Vidro |

Safe, BPA-free, handles heat, not toxic, can go in dishwasher |

Strong, does not break into pieces, lasts years |

|

Aço inoxidável |

Smooth, safe for teeth, can go in dishwasher, good for the planet |

Tough, does not break or bend easily |

|

Paper |

Good for the earth, gets soft if wet |

Rigid Fiber™ helps it keep its shape in drinks |

Straw hardness testing

Makers test how hard straws are to see if they last. Ask your supplier about their tests. Good tests help stop Common Drinkware Issues and make your drinkware last longer.

Problem 6 – Insulation Performance Issues

Causes

Insulation problems make drinks lose heat or cold fast. Your coffee might cool down quickly. Your iced water can get warm before lunch. Many things cause this issue. The bottle’s material matters most. Stainless steel with double-wall vacuum keeps drinks hot or cold longer. Glass and ceramic bottles work, but they do not insulate as well. A loose or broken seal lets heat escape. Check the lid and sealing ring often. The bottle’s size also matters. Small bottles keep drinks at the right temperature better. They have less area for heat to escape. The weather affects insulation too. Cold weather makes drinks cool down faster. Over time, the vacuum layer inside your bottle may get weak. This lowers how well it works. If you do not clean your bottle, stuff can build up inside. This makes insulation worse.

|

Fator |

Explanation |

|---|---|

|

Material of the vacuum Bottle |

Stainless steel with double-wall vacuum works best. Glass and ceramic insulate less effectively. |

|

Sealing Performance |

A tight seal keeps heat in. Loose or damaged seals let heat escape. |

|

Bottle Capacity |

Smaller bottles often insulate better. Larger bottles hold more heat but may lose it faster. |

|

Ambient Temperature |

Cold weather speeds up heat loss. Moderate climates help bottles retain temperature. |

|

Usage Duration |

Insulation can weaken over time as the vacuum layer changes. |

|

Cleanliness |

Residue inside the bottle lowers insulation. Clean regularly. |

|

Bottle Mouth Size |

Narrow mouths keep heat in better. Wide mouths are easier to clean but lose heat faster. |

|

Initial Temperature of Liquid |

Hotter drinks lose heat faster at first. Slightly cooler drinks may stay warm longer. |

Fix

You can make insulation better by checking for leaks. Clean your bottle often. Replace old seals or lids right away. If your bottle still loses heat fast, buy a new one. Pick stainless steel bottles with double-wall vacuum for best results. Always test your bottle with hot or cold water before trips.

Tip: Warm your bottle with hot water or cool it with ice water before filling it. This helps your drink stay hot or cold longer.

Prevention

Vacuum test requirement

Ask your supplier to do a vacuum test for every batch. This test checks if the vacuum layer works well. A good vacuum layer keeps drinks hot or cold for hours. Reliable suppliers will give you test results.

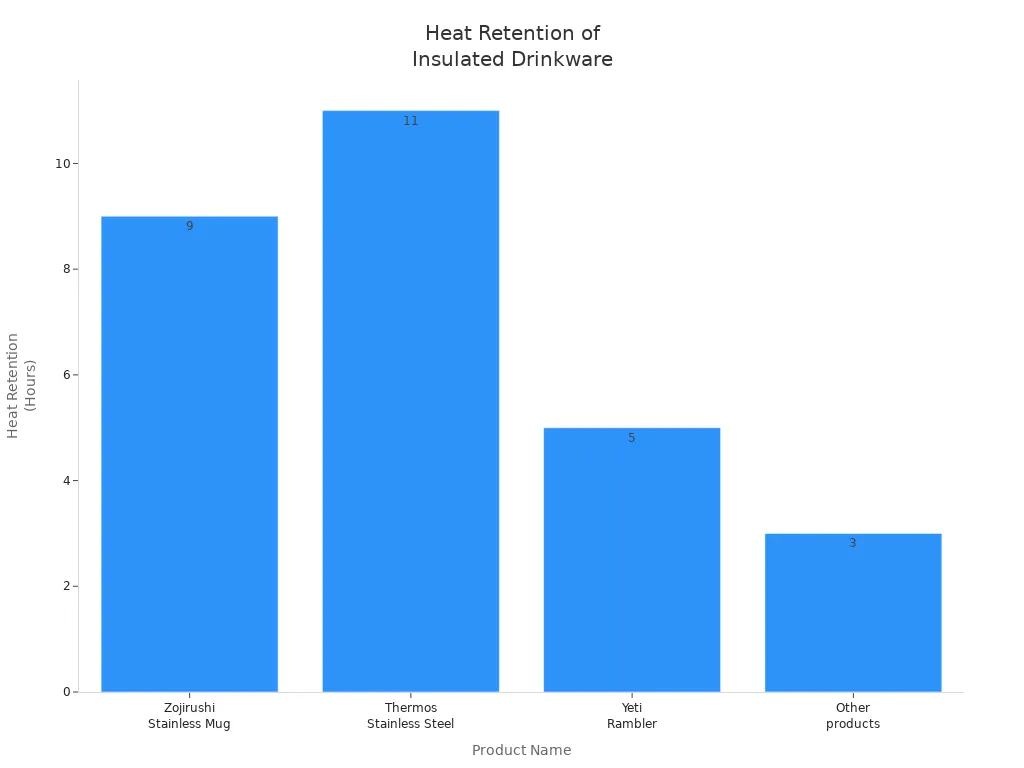

Temperature test standard

You should know how long your bottle keeps drinks hot or cold. Top brands like Zojirushi and Thermos set high standards. Zojirushi mugs keep drinks hot for up to 9 hours in cold weather. Thermos bottles last 11 hours in milder weather. Yeti Ramblers hold heat for about 5 hours at room temperature. Other bottles may only last 3 hours.

|

Product Name |

Conditions |

|

|---|---|---|

|

Zojirushi Stainless Mug SM-SF48 |

9 |

Cold conditions |

|

Thermos Stainless Steel Direct Drink |

11 |

Milder temperatures |

|

Yeti Rambler |

5 |

Room temperature |

|

Other products |

3 |

Varies |

You can avoid Common Drinkware Issues by picking bottles that meet these standards. Always ask for test reports before you buy.

Problem 7 – Strange Plastic Odor

Causes

Sometimes, new plastic bottles or cups smell weird. This smell comes from chemicals left after making the drinkware. These chemicals can make drinks taste bad. They might even hurt your health if you use the bottle every day. The most common chemicals are volatile organic compounds and leftover additives. The table below shows which chemicals cause these smells:

|

Chemical Type |

Descrição |

|---|---|

|

Volatile Organic Compounds (VOCs) |

These chemicals turn into gas and make smells at room temperature. They are found in new plastic products. |

|

Residual Chemicals from Manufacturing |

Additives like stabilizers, plasticizers, and dyes can leave strong smells. These odors can last a long time. |

Always check for strong plastic smells before you use new bottles or cups. Strange smells are a Common Drinkware Issue that people often miss.

Fix

You can get rid of most plastic smells with easy steps. Wash your new bottle or cup with warm, soapy water. Rinse it well and let it dry with the lid off. If the smell stays, fill the bottle with baking soda and water. Leave it overnight. Rinse again before you use it. If the smell does not go away, get a new bottle. Bad smells can mean the plastic is not safe.

Tip: Let new plastic bottles or cups air out for a day before you use them. This helps get rid of smells.

Prevention

Pick bottles and cups made from FDA-grade materials to avoid plastic smells. These plastics are made to stop odors from getting into your drinks. FDA-compliant plastic helps keep drinks fresh. FDA-approved glassware does not smell and is easy to clean. When you buy new drinkware, ask if the materials meet FDA rules. This helps you avoid problems and keeps your drinks tasting good.

FDA-grade material requirement

-

FDA-compliant plastic is made to stop smells from getting into food.

-

FDA-approved glassware does not smell and is easy to wash.

Choosing the right materials keeps you healthy and helps you avoid Common Drinkware Issues like strange plastic odors.

Problem 8 – Misprints or Logo Peeling

Causes

You want your logo to look good and last. Sometimes, logos peel or get misprinted because of mistakes in making the drinkware. The most common reasons are:

-

If the surface is not prepared right, ink does not stick well.

-

If the heat is wrong during printing, logos can smudge or peel.

-

Cheap materials make prints fade or fall off.

If you do not clean and prep the tumbler, the ink will not stay. If you do not know the right curing time, prints can smudge or peel. These Common Drinkware Issues can make your product look bad and hurt your brand.

Fix

If you see a misprint or peeling logo, fix it fast. Take the bad drinkware out of your stock. Talk to your supplier and ask for new ones or repairs. If you sell on Amazon, answer customer complaints quickly. Give refunds or send new items to keep your ratings high. You can use a warranty if the problem happens soon after buying.

Tip: Always check new drinkware for logo problems before you send them to customers.

Prevention

You can stop misprints and peeling logos by picking the best printing method and testing how well logos stick. Strong finishes like powder coating and sublimation keep logos bright and safe. Printing styles like silk screen, laser engraving, water transfer, and heat transfer make logos last longer.

|

Printing Technique |

Durability Characteristics |

|---|---|

|

Silk Screen Printing |

Makes clear, bright logos that last a long time. |

|

Gravação a laser |

Makes sharp, permanent marks that do not fade or peel. |

|

Water Transfer Printing |

Sticks well and resists water, fading, and wear. |

|

Heat Transfer Printing |

Gives bright, strong logos with a smooth finish. |

Logo adhesion test

Ask your supplier to test how well the logo sticks on every batch. This test checks if the logo stays on the drinkware. Good suppliers use rules to make sure logos do not peel or fade. If you ask for this test, you keep your brand safe and stop Common Drinkware Issues before they reach your customers.

Problem 9 – Color Difference Between Batches

Causes

Sometimes, your drinkware can look different from batch to batch. This can confuse buyers and make your brand look bad. Many things can change the color. You should know what happens when drinkware is made.

|

Fator |

Descrição |

|---|---|

|

Raw material fluctuations |

|

|

Differences in production |

Mixing and temperature changes can affect the shade. |

|

Changing storage conditions |

Light, heat, or air can fade or change colors. |

These things often cause Common Drinkware Issues. Always check colors before you send products to customers.

Fix

If you see color differences, act quickly. Separate items with the wrong color. Do not send them to buyers. Tell your supplier and show pictures of the problem. Ask them to check how the drinkware was made. You might need a new batch or a refund. Keep records of your orders and color samples. This helps you fix problems faster.

Tip: Look at your drinkware in natural light. This helps you see real color changes.

Prevention

You can stop color differences by making clear rules with your supplier. Use special color matching for paint and printing. Make sure your supplier uses Pantone or PMS codes for every order. At places like ZGS Glass Factory, workers clean glass before adding color. Machines spray color evenly. Each item gets checked for color and strength.

Master color sample policy

Set a master color sample rule with your supplier. Keep a sample of the right color. Your supplier uses this sample for every new batch. You should:

-

Approve a master color sample before big orders.

-

Store the sample safely for future orders.

-

Compare each batch to the master sample before shipping.

This rule helps you avoid Common Drinkware Issues and keeps your brand looking good.

Problem 10 – Packaging Damage

Causes

Packaging damage can break your drinkware before it gets to the customer. You should know what causes these problems so you can stop them. The most common reasons for packaging damage are:

-

Weak packages or not enough padding leave your drinkware open to bumps.

-

Too much empty space in the box lets items move and hit the sides. This can cause dents or cracks.

-

If your packaging gets wet and is not waterproof, it can tear or break.

-

Couriers may drop or toss boxes if there are no fragile labels.

These problems can cause dents, scratches, or even broken drinkware.

Fix

If you get a shipment with damaged packaging, act fast. Check every box as soon as it arrives. Take pictures of any damage and tell your supplier or shipping company right away. Keep all the packaging as proof. If you sell on Amazon, report the problem in Seller Central and ask for new items or money back. Always save records of damaged shipments to help with future claims.

Tip: Teach your team to look for packaging damage before sending out orders. This helps you find problems early and keeps your brand safe.

Prevention for FBA

You can stop packaging damage by following Amazon’s packaging rules. These rules help lower returns and keep customers happy.

Amazon drop-test standard

Ask your supplier to do drop tests on every batch. Drop tests check if your packaging can handle falls and rough shipping. Packaging should protect drinkware from all sides and take in shocks.

Mailbox-compatible packaging options

Pick packaging that fits in regular mailboxes. Small, tight packaging stops items from moving around. Amazon says packaging should be easy to open, safe from tampering, and made from materials that can be recycled.

|

Descrição |

|

|---|---|

|

Recyclable Materials |

Packaging must use only recyclable materials like cardboard or molded pulp. |

|

Easy to Open |

Customers should be able to open packaging without tools. |

|

Packaging must be strong enough to stop damage during shipping. |

|

|

Single Unit Packing |

Each product should ship as one unit with no extra Amazon packaging. |

|

Tamper-Resistant |

Packaging must be safe from tampering and include needed paperwork. |

|

Packaging should fit the product tightly to avoid extra space. |

If you follow these steps, you can stop packaging problems and make sure your drinkware arrives safely.

How to Prevent Drinkware Issues Before Production

Create a Detailed QC Checklist

You can stop many problems before they happen by making a strong quality control (QC) checklist. This checklist helps you find issues early and keeps drinkware safe for people. A good QC checklist checks every part, like how the product looks and tastes. Here are things you should check:

-

Look for any damage or defects you can see. 2. Check if the packaging is open or leaking. 3. Make sure labels are easy to read and have all the info. 4. See if bottles or cans look bent or odd. 5. Test if the cap or lid closes tight. 6. For fizzy drinks, check for bubbles or leaks. 7. Shake gently to listen for weird sounds or things moving. 8. Check if the color matches what you expect. 9. Smell for anything strange. 10. Taste to make sure the flavor is right and safe. 11. Feel if the drink is smooth and not lumpy. 12. Check if cold drinks are the right temperature. 13. Look for wet spots or water drops on the packaging. 14. Check for anything inside that should not be there. 15. Weigh or measure to see if the amount is correct. 16. Look for holes or damage on the packaging. 17. Make sure what is inside matches the label. 18. Check for mold, spoilage, or if it is going bad. 19. Make sure the shelf life is still good. 20. Read and follow any special warnings or instructions.

Tip: Go over your checklist with your supplier before you start making products. This helps stop Common Drinkware Issues.

Require Pre-Production Samples

Always ask for samples before making a lot of products. These samples let you see and test the drinkware first. You can check the color, logo, and if it works right. If you find a problem, you can fix it early. This saves you time and money.

Conduct Third-Party Inspection

Third-party inspections help you find more problems and make better products. These inspectors are not from your company. They check your products and the factory. They look at papers, reports, and how things are made. The table below shows what they do:

|

Descrição |

|

|---|---|

|

Supplier Vetting Checklist |

Check for certificates and papers to make sure the supplier is good. |

|

Quality Control |

Ask for reports and QC history to see if there were problems before. |

|

Site Audits |

Go to the factory to check how things are made and if it is clean. |

|

Request Samples/Pilot Batches |

Test if the products are the same and last long; good partners have less than 2% defects. |

|

Reference Checks |

Talk to other customers to learn about past problems and how they were fixed. |

|

Assess Communication |

See how fast and clear the supplier talks to you, because slow answers can cause problems. |

Note: Third-party inspectors often find problems that your own team might miss.

Work With Stable & Verified OEM Manufacturers

Pick OEM manufacturers who have a good history. Good partners show you certificates and test results. They answer fast and fix problems quickly. Stable suppliers help you avoid Common Drinkware Issues and keep your brand safe.

Final Tips for Amazon Sellers

Reduce return rate

You can lower returns by using smart steps. Better packaging keeps drinkware safe and looking nice. Good supplier checks find problems before customers get products. Helping customers after they buy stops confusion and returns. Listening to feedback helps you find and fix Common Drinkware Issues early.

|

Strategy |

Descrição |

|---|---|

|

Improve Packaging & Delivery Experience |

Use strong, branded boxes to stop damage and impress buyers. |

|

Strengthen Supplier QC & Product Checks |

Check products before shipping to catch problems early. |

|

Offer Proactive Customer Support Post-Purchase |

Give guides and help so customers use products the right way. |

|

Leverage Customer Feedback to Prevent Repeat Issues |

Study feedback to fix problems and update your listings. |

Tip: Look at your return numbers every month. This helps you see problems and fix them fast.

Improve overall product quality

You make your brand better by focusing on quality. Good drinkware lasts longer and works well. Customers notice safe materials and strong designs. Test every batch for leaks, smells, and color changes. Fixing small problems early stops bigger ones later. Keeping quality high makes customers happy and lowers complaints.

-

Test for leaks and insulation.

-

Check for paint peeling, rust, or odd smells.

-

Use FDA-grade materials and trusted suppliers.

Build long-term brand trust

Giving customers good products builds trust. People want drinkware that lasts and fits their needs. If your products stay strong and safe, buyers tell friends about your brand. Your reputation gets better over time. You become known for fixing Common Drinkware Issues and caring about health. Loyal customers buy more and help your brand grow.

Note: Trust grows when you listen to customers and keep making products better.

Choosing safe drinkware protects your health every day. You build better habits when you check your bottles and mugs for damage or odd smells. Make smart swaps for safer materials and stronger designs. Small steps like these help you avoid toxins and keep your drinks fresh.

Take action now. Review your drinkware, make safer choices, and enjoy peace of mind with every sip.

-

Inspect your current drinkware

-

Replace unsafe items

-

Share these tips with friends and family