You can make your brand stronger by making custom stainless steel bottles with the oem process. Customizing helps you meet special market needs and makes you different from other brands. Brands of all sizes get help from oem stainless steel bottles because the process uses good materials and checks quality closely.

People want bottles with cool designs and special features.

Custom choices help brands get more customers and keep them coming back.

More people want these bottles as companies look for new and earth-friendly ideas.

الوجبات الرئيسية

Custom stainless steel bottles help brands get noticed and fit what people want.

Pick OEM if you want to control design and quality. Choose ODM if you want something faster and easier.

Talk clearly with makers so your custom bottle is just how you want it.

Pick good materials and decoration to make your brand look better and build trust.

Good help after buying and easy reordering make your brand closer to customers.

OEM vs ODM for Custom Stainless Steel Bottles

Understanding OEM and ODM Services

It is important to know how OEM and ODM are different. OEM means you make your own bottle design. The factory will build it for you. ODM means you choose a bottle that is already made. You can add your logo or pick colors.

Here is a table that shows how they are not the same:

العامل | OEM (Custom Tumbler) | ODM (Ready-Made Tumbler) |

|---|---|---|

Development Cost | Higher – new molds, engineering, and prototyping required | Lower – uses existing designs, no mold fees |

Time to Market | Slower – full design and sampling process | Faster – ready-made designs can be customized quickly |

Customization Depth | Full control – structure, lid, insulation, and accessories | Limited – mainly colors, finishes, and logo |

موك | Usually higher due to tooling and production setup | More flexible, suitable for small batches |

Brand Exclusivity / Differentiation | Complete originality – unique designs for your brand | Limited – other brands may use the same base model |

Target Customers | Established brands, products needing high differentiation | New brands, startups, e-commerce sellers, promotional gifts |

Note: OEM lets you make a bottle with special features. You get more choices and control. ODM is good if you want something fast and simple.

Choosing the Right Model for Your Brand

Pick the model that matches what you want. OEM is best if you want to control the design and quality. You can make a bottle that fits your brand and is different from others. This way, your ideas and bottle design stay safe.

ODM is better if you need bottles fast or want to try selling with small orders. You can choose a bottle that is already made and add your logo or colors. This is good for new brands, online stores, or companies that need gifts.

Pick OEM if you want:

To control the design and materials

A bottle that shows your brand’s style

To keep your ideas safe

Pick ODM if you want:

Fast shipping and lower prices

Easy branding on bottles that are ready

Small orders for testing or events

Both models help you grow your brand. Think about what you need, how much you can spend, and your time before you choose.

Initial Inquiry & Requirements

Aligning Bottle Specs with Brand Positioning

You make your brand special when you pick the right specs for your custom bottle. First, think about who will buy your bottle and how it fits your brand. Choose the size, shape, and features that your customers want. For example, a sports brand might need a bottle that is light and easy to carry. A luxury brand might want bottles made with fancy materials and nice finishes.

Here is a table to help you get ready for your oem stainless steel bottles inquiry:

المعايير | التفاصيل |

|---|---|

السعة | Pick the best size (like 350ml, 500ml, or 750ml) for your buyers |

المواد | Use safe stainless steel like 304 or 316 for strong bottles |

Decoration Method | Choose laser engraving, silk screen, or heat transfer for your logo |

Compliance | Make sure your bottles follow the rules and laws |

Construction Quality | Look for bottles with smooth welding and tight seals for long use |

Tip: Make sure your bottle specs match your brand’s values and what your customers want. This helps people trust your brand and makes your spot in the market stronger.

Communicating Custom Needs to Manufacturers

Talking clearly with your manufacturer helps you get the bottle you want. Give them all the details, like drawings, color codes, and branding rules. Ask for samples so you can check if the bottles are good and strong before you order more.

When you check a manufacturer for oem stainless steel bottles, look at these things:

Find out about the manufacturer’s past work and skills.

See if they have the right licenses and quality certificates like ISO 9001 or BSCI.

Ask for samples and lots of product details.

Look at their website, social media, and business licenses.

You can also use these things to see how good they are:

المعايير | Indicators |

|---|---|

الطاقة الإنتاجية | They should have 3-5 machine lines and make over 100,000 bottles a day |

Technology Integration | They use computers and check quality all the time |

قابلية التوسع | They can add more lines and change fast if needed |

Communication Quality | They answer fast, give clear news, and have no problems |

Service Quality | They have people who speak English and help you |

Sustainability Practices | They care about the earth and follow good rules |

Note: A good manufacturer will help you avoid problems and always give you good bottles.

Design & Customization Options

Custom Stainless Steel Water Bottles: Size, Shape, Material

You get lots of choices when you design custom stainless steel water bottles for your brand. Picking the right size and shape helps you give customers what they want. It also helps people remember your brand. There are many sizes and shapes for different needs.

Small bottles (350ml) are good for kids or short trips.

Medium bottles (500ml) are great for school, work, or daily use.

Large bottles (750ml or more) are best for sports or outdoor fun.

Shape is important too. Straight bottles look cool and fit in cup holders. Curved bottles feel nice to hold. Special shapes make your bottle stand out from others.

You can pick materials like 304 or 316 stainless steel. These materials are strong and safe. They do not rust and keep drinks fresh. When you choose good materials, you show you care about quality and long-lasting bottles.

Decoration Methods: Logo, Color, Finish

There are many ways to decorate your custom water bottles. You can use laser engraving, silk screen printing, or heat transfer to add your logo, colors, and finishes.

Laser engraving makes a design that will not fade or wash off. This method is very strong. Your logo stays clear even after many washes. Laser engraving is good for small details and branding.

Silk screen printing lets you use bright colors and simple pictures. It works well for big logos or words. This method gives a smooth look and strong color.

Heat transfer printing lets you use lots of colors and cool patterns. You can make bottles that really show your brand’s style.

Decoration Method | الميزات | Best For |

|---|---|---|

النقش بالليزر | Permanent, fade-resistant, dishwasher safe | Intricate logos, durability |

Silk Screen Printing | Bold colors, smooth finish | Large logos, simple text |

Heat Transfer | Full-color, complex patterns | Artistic designs, branding |

Your design choices change how people see your brand. A logo in the right spot and special colors make your bottle easy to notice. Good finishes show you pay attention to details. When you pick the best decoration, customers trust your brand and want to buy again.

Packaging Customization

Custom packaging is important for your brand. When you design packaging, you make a strong first impression. Good packaging makes your bottles look special and professional.

Custom packaging lets you tell your brand story. You can add your logo, colors, and messages. This makes your bottles easy to remember and gets people talking about your brand. A fun unboxing experience makes people want to buy again and tell friends.

You should put important information on your packaging. Care tips and warranty details help customers use your bottles the right way. This shows you care about their experience and builds trust.

For business orders, packaging that does not need extra gift wrap saves time and money. It keeps your brand looking the same and makes your bottles ready for any event.

Tip: Pick packaging that matches your brand style. Strong packaging helps your brand and keeps bottles safe during shipping and storage.

Quotation & Sample Development

Pricing for Custom Water Bottles

You need to understand how pricing works before you order oem stainless steel bottles. The price for each bottle depends on the material, how much you want to customize, your order size, and the shipping method you choose. If you order more bottles, you usually pay less for each one. When you add special features or advanced branding, the price goes up.

Here is a table to help you see the price range and what affects it:

Price Range per Unit | Factors Affecting Price |

|---|---|

$3.00 – $12.00 | Material, customization options, order quantities, shipping methods |

If you want a small batch, like 300 units, a high-quality branded water bottle can cost around $18 each. You should always ask for a full quote that includes all costs, so you know what to expect.

Tip: Share your budget and needs with your supplier. This helps you get the best value for your custom project.

Sample Types & Approval Process

You need to check samples before you start mass production. The sample development process helps you see the real product and make sure it meets your standards. Here are the main steps:

Design & Brand Concept

You give your logo, colors, and packaging ideas to the factory. The team helps you pick the right bottle and keeps your branding consistent.Sampling & Quality Approval

The factory makes a sample in about 7–10 days. You test the sample for leaks, insulation, and how strong the coating is. You check if the custom design looks right and feels good.الإنتاج الضخم

After you approve the sample, the factory starts making your order. This step takes about 25–35 days. The team checks quality at every stage.Global Shipment

The factory packs your bottles and prepares all export documents. You can ask for special packaging, custom labels, or Amazon FBA prep.

You should always look for clear logos, smooth finishes, and strong seals. Good samples show you will get high quality in every bottle.

Order & Production

Confirming Orders for OEM Stainless Steel Bottles

After you say yes to your sample, you start the order process. You look at the final price and check the bottle details. You also decide how many bottles you want to buy. You and the factory agree on how to pay and when you will get your bottles. This step makes sure your custom design is set and the factory knows what to do.

Always check everything before you finish the order. Make sure the size, color, and logo are right. Check that the packaging is what you want. If you want a special lid or finish, write it down. Talking clearly now helps stop mistakes later.

When your order is set, the factory gets the materials. They buy strong stainless steel and other parts. The team gets the molds and tools ready for your bottle. This helps your oem stainless steel bottles match your brand’s needs.

Production Timeline & Quality Control

The factory has a plan for making your bottles. They follow steps to finish your order on time and keep quality high.

Stage | Timeframe |

|---|---|

Sample Lead Time | 5–7 days |

Mass Production Time | 25–35 days |

It usually takes 15–25 days to make your bottles after you approve the sample. If you need them faster, you might pay more. Rushing can make quality lower, so plan ahead.

The factory checks every batch for leaks and insulation. They also check the finish. They use rules from around the world to keep bottles safe.

Standard/Regulation | الوصف |

|---|---|

FDA Regulations | Makes sure bottle materials are safe for food and drinks. Checks for bad chemicals like BPA. |

ISO Standards | Gives rules for food safety and quality. Helps factories make good bottles. |

California Proposition 65 | Says factories must tell you about harmful chemicals. They try to remove these. |

EU Regulations | Sets safety rules for bottles in Europe. Bottles must pass tests before selling. |

BPA-Free Certification | Shows bottles do not have BPA. This helps people feel safe. |

You get updates about your order as it moves along. The factory tells you if there are any problems. They fix issues fast so your bottles are made right.

Tip: Talk to your supplier while they make your bottles. Ask for photos and news about your order. This helps you find problems early and keeps your project going well.

You can trust your oem partner to handle each step. They get the materials and pack the bottles. With good talking and strong checks, you get bottles that fit your brand and meet world rules.

Packaging & Shipping

Packaging for Custom Stainless Steel Water Bottles

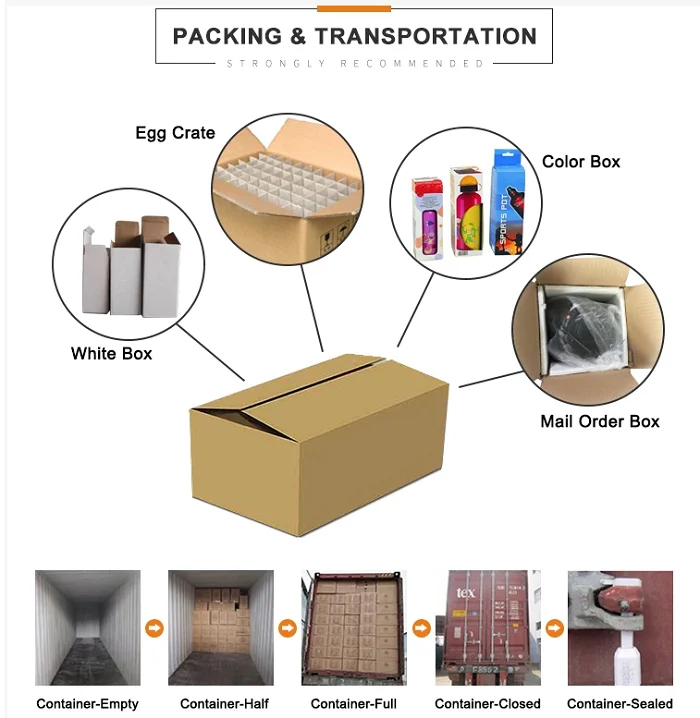

There are many ways to pack your custom stainless steel bottles. Good packaging keeps your bottles safe and makes your brand look good. You can pick a style that fits your brand and what your customers want.

Here are some popular packaging choices:

نوع التغليف | الوصف |

|---|---|

Individual Packages | These are usually in carton boxes with lids or drawer-style boxes. |

Multi-Piece Packages | Packs of 2 or 4 bottles. These are great for stores or events. |

PDQ Packages | These are boxes ready for stores. They help with fast shelf setup and show off your brand. |

Individual packages are nice for gifts or selling online. Multi-piece packs are good for families or groups. PDQ packages help your bottles stand out in stores and make restocking simple.

Tip: Pick packaging that matches your brand’s look and keeps bottles safe when shipping.

Shipping Methods & Delivery Expectations

You must follow the rules for labels and safety when you ship bottles to other countries. Labels need to show what the bottle is made of, any special marks, and how to care for it. You have to use the language of the country where you send the bottles. The packaging should be safe and earth-friendly, especially in places like the EU.

Requirement Type | التفاصيل |

|---|---|

Material Composition | Labels must say what materials are used, like stainless steel. |

Certifications | Add marks like ‘BPA-free’ or ‘recyclable’ if needed. |

Usage Instructions | Put washing and care tips for reusable bottles. |

Language Requirements | Use the local language on all labels. |

Packaging Regulations | Follow safety and green rules for each market. |

Environmental Considerations | Use packaging that can be recycled or is good for the planet. |

You can choose from different shipping ways based on your order and how fast you need it.

Method | Delivery Time | Best For |

|---|---|---|

Domestic Ground | 1–5 business days | Small or medium orders |

International Air | 5–10 days | Fast, light orders |

Ocean Freight | 14–30+ days | Big orders |

Plan your shipping early. Air shipping is best if you need bottles fast. Ocean freight is cheaper for big orders but takes more time. Always check how long delivery will take and pick the best way for your business.

After-Sales & Reordering

Support for OEM Stainless Steel Bottles

You want your brand to do well after customers get their bottles. Good after-sales support helps you fix problems fast and keeps your brand strong. Most OEM manufacturers have clear warranty rules and answer questions quickly. The table below shows how different manufacturers help with support:

الشركة المصنعة | Warranty Policy | After-sales Support |

|---|---|---|

Premium Stainless Steel Water Bottle Manufacturer | Non-defective return policy | Comprehensive after-sales support |

Stainless Steel Custom Sports Water Bottles | Strict quality requirements | 100% satisfactory after-sales service, response within 12 hours for quality issues |

If you find a problem or have a question, you can talk to your supplier. They usually answer in 12 hours and help you fix things. Many factories let you return bottles that are not right, even if they are not broken. This is called a non-defective return policy. Good after-sales service helps you trust your supplier and work with them for a long time.

Tip: Pick a manufacturer that gives fast help and clear warranty rules. This makes your business easier and keeps your customers happy.

Reordering Custom Water Bottles

If your bottles sell well, you might want to order more. Reordering with OEM manufacturers is easy and quick. You just follow a few simple steps, shown in the table below:

الخطوة | الوصف |

|---|---|

Pick A Model | Choose from many insulated coffee mug designs, with different shapes and lids. |

Design & Packaging | Update details like logo placement, colors, patterns, surface finishes, or custom packaging. |

Sampling | Review and approve new samples if you change the design or packaging. |

Scale Production | Start large-scale production with strict quality checks. |

You can make your brand new by changing the design or packaging each time you order again. If you do not change anything, you can skip the sample step and go right to making more bottles. Fast reordering helps you keep up with what people want and grow your business.

Note: Working with the same OEM supplier for a long time makes reordering easier and helps you get better service as time goes on.

Common OEM Mistakes to Avoid

When you start making custom stainless steel bottles with the OEM process, you want to avoid mistakes. These mistakes can waste your time and money. Many brands make the same errors. If you know about these problems, you can protect your brand and get better results.

Price vs Quality in Custom Water Bottles

You might want to pick the cheapest factory or only care about how your bottle looks. This can cause bad quality and upset customers. Some brands forget to check if the bottle works well. For example, they do not test if it keeps drinks hot or cold or if it leaks. Others skip important steps like testing samples or checking if the factory is good.

Here is a table of common mistakes brands make:

Pitfall | الوصف |

|---|---|

Only discussing ‘looks,’ not ‘function’ | You may forget to set clear rules for leak-proof and insulation, focusing only on appearance. |

Choosing the cheapest factory | Low prices can mean weak testing and poor quality, costing you more later. |

No clarity on testing or compliance | Missing compliance checks can delay your project and cause losses. |

Rushing timeline and skipping samples | Skipping sample checks can lead to big problems in mass production. |

Tip: Always think about both price and quality. Paying a little more can give you better materials and stronger testing. This means you will have fewer problems later.

Compliance & Communication Issues

You need to make sure your bottles follow all safety and market rules. If you do not talk clearly with your manufacturer, you might miss important details. This can cause delays or even make products you cannot sell.

Good OEM manufacturers help you avoid these problems. They use strong quality checks and have teams that know about world rules. They also help you save money by making more bottles at once and using smart ways to make them. Their research teams create new designs to keep your brand fresh. Good management helps you make better choices and keeps your project going well.

How Experienced OEMs Help | What You Gain |

|---|---|

مراقبة الجودة | Fewer defects and better products |

Cost Reduction | Lower costs and higher profit margins |

Product Research & Development | New ideas and market-ready designs |

Management Experience | Smoother projects and faster problem-solving |

Note: Work with manufacturers who help you follow the rules and keep you updated. Clear talking and strong support help you avoid mistakes and build a brand people trust.

Why Work Directly with OEM Stainless Steel Bottle Factories

Factory vs Trading Company

When you want custom stainless steel bottles, you have two choices. You can work with a factory or use a trading company. Each choice gives you different results for your brand. If you work with a factory, you get more control. You talk right to the people who make your bottles. This helps you check the quality and set rules. You also get answers quickly if you have questions.

Trading companies are in the middle. They buy bottles from factories and sell them to you. This adds another step to the process. You may not know which factory made your bottles. If there is a problem, you might wait longer for answers.

Here is a table that shows how they are different:

أسبكت | الشركة المصنعة | Trading Company |

|---|---|---|

مراقبة الجودة | Direct responsibility for quality inspection. | Indirect quality control, depends on factory. |

المهلة الزمنية | More predictable, especially for repeat orders. | Can change based on factory priorities. |

Pricing Transparency | Based on real expenses and quality of materials. | Includes additional margin for sourcing. |

Tip: If you work with a factory, you can see how bottles are made. You can ask for changes and get news fast.

Benefits of Direct OEM Partnerships

Working straight with an OEM factory gives your brand many good things. You get better bottles and faster help. You also save money because you skip the middleman. Over time, you trust the factory team more. This trust helps your brand grow and keeps your bottles good.

Your brand looks better when you work with trusted factories.

You learn more about the industry and follow safety rules.

Experts handle your order, so you have fewer problems.

You build a strong relationship that helps your brand last.

Your bottles stay the same high quality, so customers return.

You talk clearly and the process goes smoothly from start to finish.

Note: A direct OEM partnership helps you stay ahead of others. You get new ideas, better bottles, and a team that helps your brand grow.

You can make your brand bigger by using each step in the OEM process for custom stainless steel bottles. OEM manufacturing gives you good quality, saves money, and helps you make more bottles when you need to. Look at the table below to see the main benefits:

أسبكت | How OEM Helps Your Brand |

|---|---|

Technical Expertise | Consistent quality and smart design |

Cost Advantages | Lower prices for better profit |

Compliance & Certification | Safer, trusted products |

Pick manufacturers you can trust by looking at their certificates, how they help you, and if they can change when you need them to. Working with the same OEM company for a long time helps you keep up with new trends and keeps your brand strong in a busy market.

الأسئلة الشائعة

How long does the OEM process for custom stainless steel bottles take?

You can expect the full OEM process to take 30 to 45 days. This includes design, sampling, production, and shipping. Timelines may change based on order size and customization level.

What is the minimum order quantity (MOQ) for custom bottles?

Most factories set the MOQ at 300 to 500 pieces. Some manufacturers offer lower MOQs for simple designs or trial orders. You should confirm this with your supplier before starting.

Can you customize both the bottle and the packaging?

Yes, you can customize both. You choose the bottle’s size, color, and finish. You also design the packaging with your logo, colors, and special messages. This helps your brand stand out.

What certifications should your custom bottles have?

You should look for FDA, LFGB, or BPA-free certifications. These show your bottles are safe for food and drinks. Ask your supplier for proof of compliance before you order.