In the fast-growing hydration industry, buyers and distributors are becoming increasingly selective about where their stainless steel bottles come from and how they are made. Retailers, wholesalers, and private-label brands want reliability, safety, and consistent quality—especially when sourcing stainless steel water bottles, insulated water bottles, or other reusable drinkware for large-scale distribution.

To make informed purchasing decisions, understanding the complete manufacturing and quality-control process is essential. This transparency not only helps prevent after-sales issues but also enables long-term cooperation with a trustworthy stainless steel water bottle supplier.

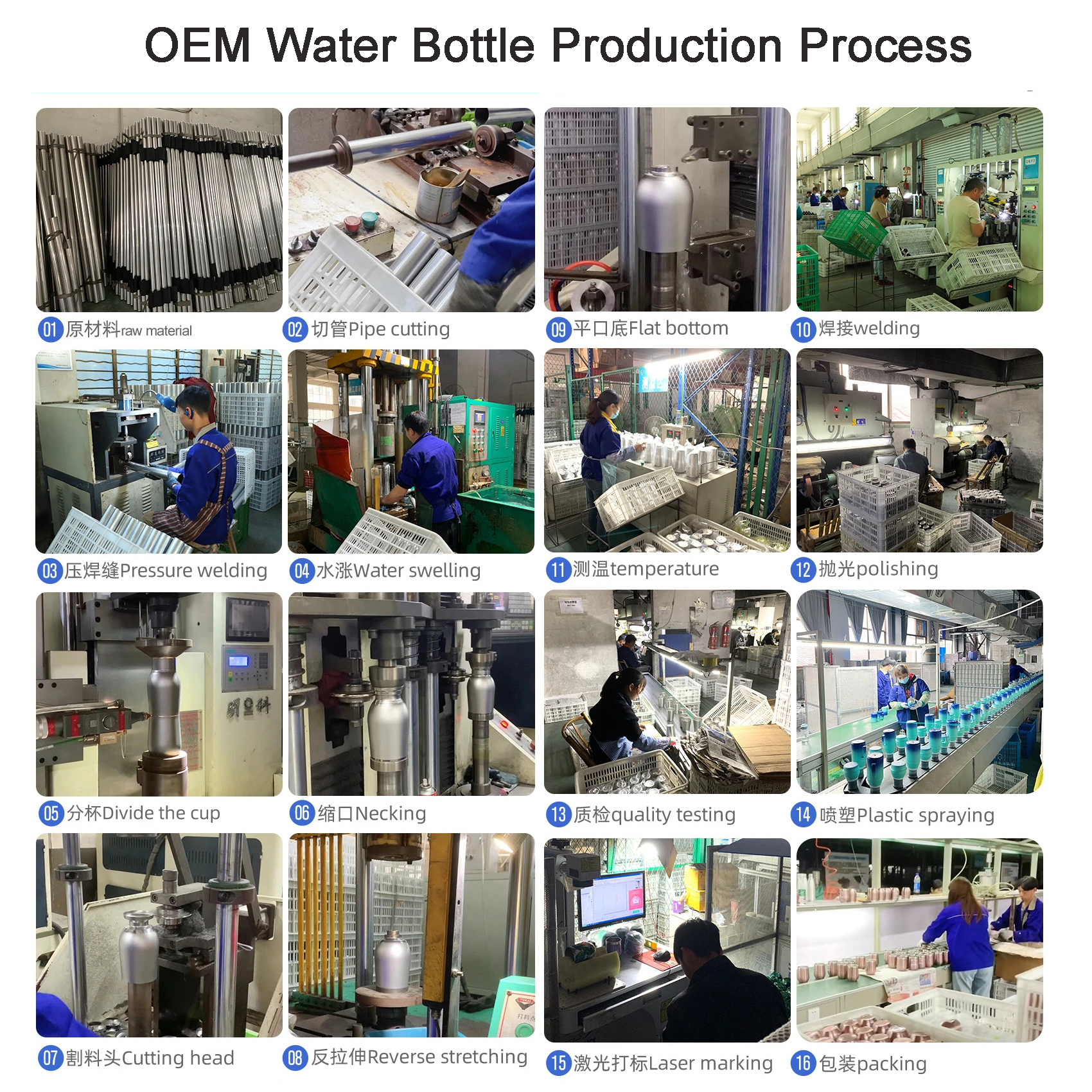

This article takes you on a full journey, from raw materials to finished products, demonstrating how a professional factory ensures durability, performance, and safety in every bottle manufactured for bulk water bottles for export.

Understanding Why Production Transparency Matters

The global shift toward sustainable lifestyles has significantly increased the demand for stainless steel bottles. But with rising demand comes greater variation in product quality. For wholesalers, transparency offers valuable advantages. It allows you to evaluate whether a factory uses genuine food-grade stainless steel, whether they possess reliable vacuum insulation technology, and whether their quality-control system minimizes defects and shipment risks.

Knowing the true production process also helps importers avoid hidden pitfalls such as inconsistent wall thickness, poor insulation performance, leaking lids, or weak coatings. A transparent manufacturer not only protects your reputation but also supports your business as it grows into new markets.

Raw Materials as the Foundation of a Great Bottle

Every premium bottle begins with the right material. Most stainless steel bottle factories rely on food-grade stainless steel, especially 304 stainless steel (18/8), known for its corrosion resistance and durability. For high-end models, 316 stainless steel may be used for even stronger protection against salt and chemicals.

Other essential components such as Tritan lids, PP elements, and silicone seals must also meet international safety standards. Before production starts, raw materials undergo strict checks for quality certificates, composition verification, and visual inspection. Choosing the correct material is crucial because it directly impacts durability, hygiene, and the final user experience.

Forming the Bottle Body Through Deep Drawing

The production process begins by cutting stainless steel sheets into circular discs. These discs are then formed into bottle bodies using hydraulic deep-drawing machines. The metal expands uniformly under high pressure, shaping the bottle interior and exterior simultaneously.

Uniform wall thickness at this stage is vital for achieving reliable insulation performance later. Factories use precision machinery to ensure each cup or bottle shell meets the exact dimensions required for the next stages of production.

Shaping, Trimming, and Neck Forming for Consistency

After drawing, bottle bodies are trimmed to a clean, even height. The neck is then shaped depending on the bottle style—whether it’s a wide-mouth bottle, a coffee tumbler, or a sports-style insulated bottle.

For customized designs, factories create specialized molds that match a brand’s unique aesthetics. This is especially important for wholesalers seeking exclusive product lines or differentiation in competitive markets.

Welding and Seam Refinement

Some bottles, particularly those with handles, bases, or special structures, require precise welding. TIG welding is commonly used to fuse components seamlessly. After welding, the seam is polished until smooth, ensuring that the joint is both strong and visually clean.

Strong welds contribute to long product lifecycles and help bottles pass international durability tests without issue. This is especially relevant for buyers distributing bottles for outdoor, sports, or corporate gifting markets.

Polishing for Hygiene and Aesthetics

Polishing serves two purposes: improving hygiene and preparing the bottle for coating or branding. A well-polished inner surface ensures that drinks do not retain odors or flavors, while outer polishing creates a smooth base for paint or powder coating.

Professional factories implement multiple rounds of polishing to remove imperfections, maintain consistent texture, and enhance the bottle’s final appearance.

Creating Vacuum Insulation: The Heart of an Insulated Bottle

Double-wall vacuum insulation is the signature technology behind premium insulated water bottles. Two stainless steel layers are assembled, and the air between them is extracted to create a vacuum barrier that prevents heat transfer.

This process requires precise technology and strict leak prevention. Each insulated bottle undergoes performance checks to verify how long it can retain temperature, ensuring the final product meets global expectations for hot-and-cold retention.

Strong insulation is a major selling point for retailers, especially for outdoor sports, office hydration, and lifestyle markets.

Leak Testing to Guarantee Functional Safety

A critical step in the production line involves leak testing. Factories typically perform both air-pressure and water-pressure tests to ensure that each bottle—or each batch—meets strict leak-proof requirements.

Since leakage is one of the most common customer complaints in the hydration industry, a factory that performs 100% leak testing can dramatically reduce return rates and protect a brand’s reputation.

Surface Finishing Options for Brand Identity

Stainless steel bottles can be finished in various styles depending on your brand identity and target market. Common finishing options include:

- Powder coating for durability and scratch resistance

- Spray paint for high color flexibility

- Electrolysis for premium corrosion resistance

- Matte or glossy finishes for different aesthetic preferences

- Gradient tones, pearl effects, and soft-touch coatings for modern market trends

Wholesalers can choose finishes that align with their customer demographics, such as minimalist matte tones for corporate gifts or bright gradients for fitness and outdoor consumers.

Adding Logos and Custom Branding

Branding transforms a standard bottle into a marketable product. Factories offer multiple printing methods such as laser engraving, silk screen printing, UV printing, and heat transfer.

Each method serves a different purpose. Laser engraving provides a permanent premium logo, while UV printing allows full-color artwork. For B2B clients and bulk water bottles for export, customization is often the most important factor in standing out among competitors.

Assembly of Lids and Accessories

During assembly, technicians install lids, silicone gaskets, handles, and other accessory parts. Compatibility checks ensure that each lid fits perfectly onto the bottle body, preventing leakage and ensuring a smooth user experience.

Proper assembly is especially important for bottles intended for outdoor use or sports hydration, where strong performance and durability are essential.

Factory Quality Control Based on International Standards

A professional stainless steelwater bottle supplier follows a multi-layered quality-control system that includes inspections at every production stage. Final inspections typically include leak tests, insulation performance checks, adhesion tests for paint, logo accuracy checks, drop tests, odor tests, and verification of packaging integrity.

A strict QC system acts as the final guarantee that bottles meet export requirements and customer expectations.

OEM and ODM Support for Brand Differentiation

Factories that offer complete OEM and ODM services help businesses scale faster. This includes mold development, packaging design, color matching, product engineering, and branding assistance. For wholesalers preparing to enter new markets or expand their catalog, professional factory support ensures smooth production and strong market appeal.

Production Capacity and Lead Times for Bulk Orders

A capable factory maintains stable daily outputs, allows for flexible customization, and offers fast turn-around time for samples and mass production. These advantages ensure that distributors, retailers, and corporate clients receive timely deliveries throughout seasonal demand cycles.

How Manufacturers Prevent Common Defects

Professional factories apply multiple preventive measures to reduce issues such as paint peeling, vacuum failure, leaks, scratches, or odor problems. Advanced inspection equipment and strict training help maintain high consistency, especially for large export orders.

These preventive measures significantly reduce after-sales issues and strengthen trust between suppliers and global buyers.

Export-Ready Packaging for Safe Global Shipping

Export packaging requires durability and careful structure. Factories typically use drop-tested cartons, eco-friendly kraft boxes, custom gift boxes, or retail-ready packaging. Proper labeling and palletization guarantee that bottles arrive safely in warehouses or fulfillment centers such as Amazon FBA.

Safe packaging protects both the product and the brand reputation of wholesalers.

Why Choosing the Right Manufacturer Matters

Selecting the right bottle manufacturer influences the long-term success of your brand. A factory with strong insulation technology, reliable QC systems, stable production capacity, and comprehensive OEM services will consistently deliver products that meet market expectations.

A strong supplier relationship ensures better communication, faster development cycles, lower defect rates, and higher customer satisfaction—critical elements for businesses distributing stainless steel water bottles or insulated drinkware worldwide.

Frequently Asked Questions for Wholesalers

How long can an insulated bottle keep beverages hot or cold?

Most well-made bottles maintain temperature for several hours, depending on lid structure and vacuum performance. Ifun stainless steel bottles generally can keep hot up to 70℃ after 12hours, and keep cold for up to 6 hours.

Can factories provide customized colors and logos?

Yes, most suppliers support Pantone color matching, personalized branding, and packaging design. Ifun provide OEM and ODM service to meet your custom requirements.

What certifications are required for importing reusable bottles?

The most certifications include LFGB, FDA, and BPA-free compliance. Ifun provide FDA and LFGB certificate for checking.

What is the minimum order quantity for custom designs?

Most factories offer flexible MOQs. Ifun support moq of 100pcs for custom logo or design on the bottles.

From raw material selection to the final QC inspection, the entire production chain behind a stainless steel bottle requires precision, technology, and strict management. For wholesalers and distributors searching for bulk water bottles for export, understanding the process makes it easier to choose a reliable provider, avoid risks, and maintain brand reputation.

A dependable stainless steelwater bottle supplier serves not just as a manufacturer but as a long-term partner that supports innovation, customization, and business growth. With transparency, technical expertise, and strong customization capabilities, wholesalers can build profitable hydration product lines that meet global consumer expectations.