You should pick the right tumbler supplier by knowing your business needs. You also need to know who you want to sell to. In 2026, many new brands see that choosing a custom tumbler manufacturer depends on if you want OEM or ODM for big orders. Personalized tumblers help you reach customers who like special and good products. Companies use custom logo tumblers as gifts for workers or clients. This helps people remember their brand. If you read reviews and feedback, you can find out which tumbler supplier has good quality. Always choose a supplier that fits your long-term plans.

Why Custom Tumblers Are Booming in 2026

Corporate gifting & promotional demand continues to rise

More companies now give tumblers as gifts. They give them to workers and clients. Businesses want to give things people use every day. Tumblers with logos help people remember a brand. Many groups pick drinkware for trade shows and holidays. They also use them for employee rewards. This makes the tumbler market grow each year. Companies like gifts that are useful. These gifts show thanks and help build loyalty. Picking a good tumbler shows your brand cares about style and function.

DTC brands and TikTok trends driving new tumbler designs

DTC brands have changed how you buy drinkware. You can find special designs and limited editions online. Social media, like TikTok, spreads tumbler trends fast. Viral videos show off new colors and patterns. When a design gets popular, the market reacts quickly. Factories make new styles to match what is trending. You can use these trends to reach younger buyers. They want the newest look. DTC brands work with influencers to boost sales and create excitement.

Note: The custom tumbler market may grow from USD 3.75 billion in 2025 to USD 4.15 billion in 2026. This means it could grow about 10.6% in one year.

Small-batch private label customization becomes mainstream

You do not need to order thousands of tumblers now. The tumbler market lets you order small batches for your brand. You can try new designs or colors with less risk. Many factories let you order small amounts and offer custom options. You can add your logo or pick special finishes. You can also make seasonal collections. This helps new brands join the market and compete. Small-batch orders let you react fast to feedback and trends.

When you look at all these trends, you see why the tumbler market keeps growing. You have more ways to reach buyers, try new ideas, and build your brand with good drinkware.

Sustainability shift toward stainless-steel drinkware

In 2026, the drinkware industry is changing a lot. Brands care more about sustainability now. Stainless-steel tumblers are very popular with eco-conscious buyers. People want products that last a long time and make less waste. Stainless steel is strong, can be used again, and can be recycled.

Many people do not want single-use plastics anymore. Buyers often ask what their drinkware is made of. They want to know if your tumblers help the planet. Stainless steel is a good answer for these questions. You can tell customers your products do not have chemicals that leach out. You also show your brand cares about health and safety.

You get many benefits when you pick stainless-steel tumblers:

Long lifespan: Stainless steel does not dent or scratch easily. Your products can last for many years.

Recyclability: You help the circular economy. Stainless steel can be recycled over and over.

No harmful chemicals: You do not use BPA or other toxins in plastic. Customers trust your brand more.

Easy cleaning: Stainless steel does not keep smells or stains. Buyers can clean their tumblers easily.

Premium look and feel: Your product feels solid and looks modern. This helps your brand stand out.

Consejo: You can talk about your sustainability in your marketing. Use words like “eco-friendly,” “reusable,” and “BPA-free” on your packaging and website. This brings in buyers who care about the earth.

There are new rules in many places now. Governments want less plastic waste. You need to follow these rules to sell worldwide. Stainless-steel tumblers help you meet these laws. You will not get fined and your business stays safe.

You can choose manufacturers who use recycled steel. This makes your brand look better. You show you care about every part of making your product. You also get buyers who want ethical sourcing.

You should ask your supplier where their materials come from. Ask for certificates that show the steel is food-grade and safe. You also want to know if they follow green standards. This keeps your brand safe and builds trust.

Sustainability is not just a trend anymore. It is something all new brands must do. You need to pick materials that fit your values and your customers’ needs. Stainless-steel drinkware helps your brand grow strong in 2026.

Best-Selling Tumbler Styles for Brands (2026)

Stanley-style tumblers

Core specifications brands should follow

Stanley-style tumblers are very popular with new brands in 2026. People see these tumblers everywhere because they look good and work well. If you pick this style, you need to think about some important things:

Material: Pick food-grade stainless steel. This keeps the tumbler safe and strong.

Capacidad: The best sizes are 30oz and 40oz. These sizes help people stay hydrated.

Aislamiento: Double-wall vacuum insulation keeps drinks cold for a whole day. It also keeps drinks hot for up to 12 hours.

Diseño de la tapa: Use lids that do not leak. Add handles that are easy to carry.

Color Options: Give buyers lots of colors to choose from. Limited edition colors are great for people who like trends.

Eco-Friendly: Use recycled materials. This is good for customers who care about the planet.

The Stanley trend got big on social media. Gen Z and millennials like the useful design y special color releases. You can help your brand by making custom colors and cool packaging.

Key factors affecting Stanley-style OEM cost

Many things change the price when you buy Stanley-style tumblers from an OEM supplier:

Material grade: Better steel costs more but lasts longer.

Mold complexity: Special molds for new shapes or handles cost extra at first.

Order quantity: Buying more tumblers makes each one cheaper. Small orders cost more for each tumbler.

Surface treatment: Fancy finishes like powder coating or color fades cost more.

Packaging: Nice packaging, like gift boxes, makes the price go up.

You need to match what you want with how much you can spend. If you use regular molds and simple finishes, you can save money and still have a nice tumbler.

Tumbler Style | Sales Volume | Peak Sales Month | Notas |

|---|---|---|---|

Vasos de acero inoxidable | November 2025 | New brands sell the most of these in bulk. | |

Personalized Tumblers | N/A | N/A | More people want these, but sales are lower than stainless steel. |

Licensed Tumblers | N/A | N/A | More people are interested, but sales are not as high as stainless steel. |

YETI-style tumblers

Insulation performance & durability standards

YETI-style tumblers are known for keeping drinks hot or cold for a long time. These tumblers keep drinks cold for a whole day and hot for up to 6 hours. Compared to Stanley tumblers, YETI loses just one more degree when keeping drinks cold. YETI tumblers are better at not leaking. People trust these tumblers for outdoor trips and daily use.

Característica | YETI Tumblers | Stanley Tumblers |

|---|---|---|

Cold Retention | Drops 1 degree more than Stanley | Keeps cold for 24 hours, drops 1 degree |

Heat Retention | Stays hot for up to 6 hours | Stays warmer than YETI, still warm after 24 hours |

Resistencia a las fugas | Leaks less | Leaks more |

Powder coating and surface treatment options

How the tumbler looks and lasts depends on the surface treatment. Powder coating gives a matte or shiny look. It also stops scratches and fading. Some brands use color fades or shiny finishes to look different. When you want to customize, ask your supplier what finishes they offer. A good finish keeps your tumbler looking new for a long time.

Simple Modern–style tumblers

Slim silhouette, gradient finishes, clean design

Simple Modern–style tumblers are for people who like a modern and simple look. These tumblers are slim and fit in cup holders and bags. You can use color fades for a cool style. Clean lines and small logos make the tumbler look fancy. Many new brands pick this style because it works for many people and looks good in stores. If you use simple designs and special finishes, your brand will stand out.

Travel mug & coffee mug styles

Leakproof lid types (flip, slider, auto-seal)

When you pick travel mugs or coffee mugs for your brand, you should think about what your customers want most. In 2026, people want more than just a plain mug. They look for mugs that fit their busy lives and keep drinks hot and safe. A good lid design helps your mug get noticed.

Leakproof lids are very important for brands and buyers. You can pick from a few popular lid types:

Flip lids: These lids open with a quick flip. You can use them with one hand. Many people like them for fast drinks when they are busy.

Slider lids: These lids slide open and closed. They stop spills and keep drinks hot. You can move them to sip or seal the mug.

Auto-seal lids: These lids close by themselves after you take a sip. They use a button or special part. They are best for stopping leaks. People who travel or go to work like this style.

Tip: To avoid problems, always test your lids for leaks before you buy a lot.

You should also think about other things that make travel mugs and coffee mugs popular in 2026. The table below shows what brands ask for most:

Característica | Descripción |

|---|---|

Conservación de la temperatura | Needed to keep drinks hot for a long time. Double-wall vacuum insulation works best. |

Tapas herméticas | Stops spills when you travel. Makes mugs easier to use. |

Customizable finishes | Lets you add special designs or logos. Good for gifts or branding. |

Ergonomic shapes | Feels good to hold and easy to grip. Makes using the mug better. |

Double-wall vacuum insulation is still very important. It keeps coffee or tea hot for many hours. Your customers will like mugs that stay warm during long trips or meetings. Ergonomic shapes are also important. Mugs that fit well in your hand or cup holder are easier to use every day.

Customizable finishes let you make your mugs special. You can put your logo on them, pick cool colors, or make limited editions. This makes your mugs great for company gifts or events. Many brands use these mugs to help people remember their name.

When you talk to a manufacturer, ask how they test their lids. Good suppliers will show you leakproof test results. You should ask for samples and try the lids yourself. This helps you avoid mistakes and makes sure your mugs are good for your customers.

If you want to sell more products, you can offer travel mugs with a the same style tumbler. This gives your customers more choices and makes your brand stronger. In 2026, paying attention to details and quality will help your mugs beat the competition.

OEM/ODM Manufacturing Process (Step-by-Step)

Step 1: 3D design & technical drawing

You start by making a 3D design and technical drawing. This helps you see what your tumbler will look like. You work with engineers to make digital models. These models show the tumbler’s shape and how the lid fits. The drawings help you tell the manufacturer what you want. You can change the design to match your brand. You might add a logo or pick a special shape.

A good drawing has sizes, materials, and how to put it together. You should check these drawings before moving on. This step takes one to three weeks for most stainless steel tumblers. If you need it fast and only want a simple logo, it can take just a few days.

Tip: Ask your supplier for digital previews and 3D pictures. These help you find problems early and save money.

Step 2: Mold creation & prototype testing

After you like the design, the factory makes molds and tests a prototype. They use your drawings to build molds for the tumbler parts. You get a sample to check how it looks and feels. This step is important for testing your custom ideas.

You may have some problems during this step:

You need a supplier you can trust as you make more.

Good inventory management stops you from running out or having too much.

Automatic quality checks keep your products good.

Design issues can happen, like lids not fitting after washing.

It is hard to keep sizes the same when making many tumblers.

Materials may act differently when you make a lot.

Tools can wear out and slow things down.

You rely on your supplier for steady quality.

Guessing how many to make can be hard.

Checking quality gets harder with more tumblers.

You should test the sample for leaks, insulation, and strength. If you find a problem, you can fix the mold before making a lot. Making molds and testing samples usually takes one to three weeks for stainless steel tumblers.

Step 3: Stainless-steel forming & vacuum process

When you approve the sample, the factory shapes the stainless steel. Workers use machines and molds to make the tumbler body. The vacuum process adds double-wall insulation. This keeps drinks hot or cold for a long time. You must make sure the factory uses food-grade stainless steel.

The table below shows how long different materials and options take:

Material / Customization | Estimated Lead Time |

|---|---|

Standard stainless steel | 1–3 weeks |

Rush orders (simple logos) | 3–7 days |

Glass tumblers (custom) | 12–13 weeks |

You should ask your supplier about how they form and insulate the tumblers. A good factory will tell you about their machines and quality checks. This step makes sure your tumbler is strong and keeps drinks at the right temperature.

Step 4: Surface treatment (polishing, powder coating, gradients)

You have to pick the best surface treatment for your custom tumblers. This step changes how your tumbler looks and feels. It also makes your tumbler last longer and helps people notice your brand. Factories use different ways to finish stainless-steel tumblers. Polishing makes the tumbler shiny and smooth. This finish gives your tumbler a fancy look. Powder coating adds color and texture to the tumbler. You can choose matte, glossy, or rough finishes. Powder coating keeps the tumbler safe from scratches and fading. Gradients are very popular in 2026. Factories use special sprays to mix colors together. This style is good for buyers who want something different.

Tip: Ask your supplier to show you samples of each finish. You can see and feel them before you make a choice.

Surface treatment helps your brand get noticed. You can match tumbler colors to your logo or holiday themes. Some factories can make colors that match your brand. You should check if the finish is safe for dishwashers. A good finish keeps your tumbler looking nice after many washes.

Surface Treatment | Características | Lo mejor para |

|---|---|---|

Pulido | Shiny, smooth, easy to clean | Premium brands |

Recubrimiento en polvo | Matte, glossy, textured, durable | Everyday use, gifting |

Gradient Spraying | Multi-color, trendy, eye-catching | Limited editions, DTC |

Step 5: Logo printing & decoration

You want people to see your brand on every tumbler. Logo printing and decoration make your tumbler special. In 2026, factories use new ways to add logos. You can pick the method that fits your brand and budget.

Grabado por láser makes a clear and lasting mark. It works well on stainless steel. Your logo will not come off or fade.

Silk screen printing lets you use bright colors and cool designs. This way is good for big orders and simple logos.

Embossed and debossed styles make the logo stick out or go in. These ways add texture and make the tumbler feel fancy.

3D printing lets you make detailed decorations and layered logos. You can use this for special or expensive tumblers.

Note: Always ask for a sample with your logo before you order a lot. This helps you catch mistakes and makes sure your brand looks good.

Think about how big your logo should be and where to put it. Big logos are good for gifts. Small logos look nice for fancy brands. You can also use full-wrap printing and special patterns. You can mix printing styles for a cool look.

Step 6: Assembly & final packaging

After you decorate the tumblers, they go to assembly. Workers put on lids, handles, and silicone seals. Every part must fit just right. You should check that the lids do not leak and are easy to use. Factories use machines for big orders. People put them together by hand for small orders or hard designs.

Final packaging keeps your tumbler safe when shipping. You can pick plain boxes or special gift boxes. Good packaging makes your tumbler worth more and helps your brand stand out. You should ask your supplier for eco-friendly packaging. Many people want recyclable boxes in 2026.

Tip: Ask for drop and shake tests for your packaging. This makes sure your tumblers get to customers safe and not broken.

You can add care tips or ads inside your packaging. These extras help customers like your brand more. Tumblers that are put together and packed well show you care about quality.

Step 7: Full QC inspection (drop, leak, insulation tests)

You need to make sure every tumbler meets high standards before you ship it. Full QC inspection is the last step in the OEM/ODM manufacturing process. This step helps you catch problems and protect your brand reputation. You want your customers to trust your products. You must check for leaks, insulation, and durability.

Prueba de caída

You should start with the drop test. Workers drop the tumbler from a set height, usually one meter, onto a hard surface. This test checks if the tumbler dents, cracks, or breaks. You want your tumblers to survive daily use. If the tumbler fails, you need to fix the design or choose better materials.

Prueba de estanqueidad

Next, you need to test for leaks. Fill the tumbler with water and close the lid tightly. Turn the tumbler upside down and shake it. Look for any drops or spills. A good tumbler does not leak, even when you carry it in a bag. You should test different lid types, like flip, slider, or auto-seal. If you find leaks, ask your supplier to improve the lid design.

Insulation Test

You must check how well your tumbler keeps drinks hot or cold. Fill the tumbler with hot water and measure the temperature after six hours. Do the same with cold water and ice. Compare the results to your brand’s promises. Good insulation means happy customers. If the tumbler loses heat or cold too fast, you need to review the vacuum process or wall thickness.

Consejo: Ask your supplier for a QC report with photos and test results. This helps you see how each batch performs.

QC Checklist Table

Tipo de prueba | What You Check | Pass Criteria |

|---|---|---|

Prueba de caída | Dents, cracks, broken parts | No damage after drop |

Prueba de estanqueidad | Water leaks, lid fit | No leaks after shaking |

Insulation Test | Temperature loss over time | Meets promised retention |

You should approve samples before mass production. You need to check random tumblers from each batch. This helps you catch problems early. You can also ask for third-party lab tests for extra safety.

Quality control protects your brand. You show customers you care about safety and performance. You build trust and get repeat buyers. Always make QC inspection a top priority in your tumbler business.

Tumbler Customization Options (2026 Upgrade List)

Powder coating finishes

Matte, glossy, textured

You have a few powder coating finishes to pick from for your tumbler. Matte finishes make your tumbler look soft and smooth. Glossy finishes are shiny and bright. Textured finishes feel bumpy and help you hold the tumbler better. Each finish makes your tumbler look and feel different.

Powder coating keeps your tumbler safe from scratches and fading. It makes the tumbler last longer, even if you use it every day. Many brands use powder coating to match their logo colors or for special times of year. You can ask your manufacturer for samples before you choose. This helps you see which finish is best for your brand.

Finish Type | Appearance | Beneficios | Best Use |

|---|---|---|---|

Matte | Soft, non-reflective | Modern look, hides fingerprints | Everyday tumblers |

Glossy | Shiny, reflective | Premium feel, easy to clean | Gift tumblers |

Textured | Raised, tactile | Better grip, unique style | Sports tumblers |

Tip: Powder coating works for both small and big orders. You can use it for special editions or your main products.

Gradient colors

Best-selling color trends for 2026

Gradient colors are very popular for tumbler customization in 2026. You see these colors everywhere, like on social media and in stores. Gradients mix two or more colors together on the tumbler. This makes the tumbler look new and cool.

Some top color trends for 2026 are pastel blends, sunset fades, and metallic gradients. Brands use gradients for special collections or holiday products. You can pick colors that match your brand or follow what is popular.

Pastel blue to pink

Sunset orange to yellow

Metallic silver to teal

Forest green to lime

You can ask your supplier for a color chart or a digital preview. This helps you pick the best gradient for your customers. Gradients work well with powder coating and other finishes. You can mix finishes to make your tumbler stand out.

Note: Gradient customization needs special spraying machines. Make sure your manufacturer knows how to do this.

Full-wrap printing

UV printing / heat transfer / water transfer

Full-wrap printing lets you cover the whole tumbler with your design. You can add your logo, artwork, or any picture you want. In 2026, there are three main ways to do this:

Impresión UV uses special light to dry the ink. You get clear pictures and bright colors. This is good for detailed designs.

Heat transfer uses heat and pressure to put your design on the tumbler. You get a smooth finish and strong stick. This is best for big orders and simple designs.

Water transfer wraps designs around curved parts of the tumbler. You can use this for patterns, photos, or cool effects.

You can mix these printing methods for special or limited tumblers. Full-wrap printing helps your brand get noticed by more people. Always ask for a sample before you order a lot. This makes sure your design looks right on every tumbler.

Printing Method | Lo mejor para | Durabilidad | Color Range |

|---|---|---|---|

Impresión UV | Detailed logos, photos | Alta | Wide |

Heat Transfer | Simple patterns, text | Medio | Medio |

Water Transfer | Complex wraps, effects | Alta | Wide |

Tip: Full-wrap printing works best on smooth tumblers. Ask your supplier if it works with powder coating and gradients.

Grabado por láser

When engraving is better than printing

Laser engraving is a great way to put your brand on tumblers in 2026. This method gives you very clear and detailed designs. You can see small lines and shapes on stainless steel. Many brands pick engraving when they want their logo to look neat and sharp.

You should use laser engraving if you want your design to last a long time. Printed designs can fade or chip after many washes. Engraved logos stay on the tumbler for years. This means people will see your brand even if they use the tumbler a lot. Your logo will also stand out in public places, so more people notice your brand.

Laser engraving has many good points compared to printing:

You get high-quality logos with lots of detail.

The design stays clear after washing many times.

This process does not use any chemical inks or strong cleaners, so it is better for the environment.

You can make many tumblers quickly and save money because the quality stays the same.

It might cost more at first, but it saves money over time because the design lasts longer.

Your brand message stays easy to see for years, so it works well for advertising.

If you want your tumbler to look good for a long time, engraving is the best choice. You also help the planet, which is important to many buyers in 2026. Laser engraving is perfect for fancy tumbler sets and gifts. You can also mix engraving with other ways to decorate for a special look.

Custom lid development

Leakproof structure & silicone components

Custom lid development is very important for making special tumblers. You need to give your customers lids that look good and work well. Leakproof lids and silicone parts help you make tumblers people can trust.

In 2026, many brands want new lid features. You can pick lids with flip, slider, or auto-seal parts. Silicone seals stop leaks and are easy to clean. Some factories let people design their own lids. You can add cool patches or colors to make each lid different.

Here are some custom lid features brands ask for:

Característica | Descripción |

|---|---|

Build-A-Cap Kiosks | Interactive kiosks allowing customers to create unique cap designs. |

Hat Curving Machines | Machines that enable customers to curve their hats to their preference. |

Unique Patches | Approximately 40 unique patches tailored to local markets available for customization. |

Lids that do not leak and have silicone parts make using the tumbler better. You will have fewer spills and cleaning is simple. These features also help your brand get noticed by more people. You can change lids to match holidays or special events.

When you talk to a factory, ask how they test their lids. Good suppliers will show you samples and test results to prove their lids do not leak. You should always check how the silicone seals fit and work. A good lid design helps your brand look smart and creative.

Desglose de costes

Steel grade (304 vs 316)

When you pick the steel grade, you choose how your tumbler works and how much it costs. Most brands use Acero inoxidable 304. It is strong and safe for food. If you want your brand to stand out, you can use 316 stainless steel. This steel is better at stopping rust and has a smooth finish. You pay more for 316, but your tumbler looks fancier and helps your brand look better.

316 stainless steel costs about 20-40% more than 304.

The higher price is because of molybdenum and extra steps.

You can sell your tumblers for more money if you use 316.

Many buyers think 316 means top quality and good materials.

You can charge more when you use 316 stainless steel.

If you want to save money and still have good quality, compare both grades. For most people, 304 is good for daily use. If your brand is about luxury or health, 316 is the best choice.

Surface treatment type (powder, gradient, electroplating)

Surface treatment changes how your tumbler looks and feels. It also changes the price and how long it takes to make. You can pick powder coating, gradient spraying, or electroplating. Each one has its own cost and order rules.

Minimum Order Quantity (MOQ) | Turnaround Time | Setup Fee | Imprint Cost per Item | |

|---|---|---|---|---|

Single-Color Customization | ~12 dozen | 10-15 business days | $95-$105 | $0.55 – $0.65 |

Multi-Color Customization | 417-590 dozen | 8-12 weeks or more | $175-$195 per color | Varies by complexity |

Hot Stamp | 417-590 dozen | 8-12 weeks or more | Varies by artwork | Included in unit price |

Custom Color | 600-800 dozen | ~12 weeks | N/A | N/A |

Powder coating gives a tough finish and lots of colors. Gradient spraying makes cool styles but needs special machines and bigger orders. Electroplating adds a shiny layer and is best for fancy brands. You should ask your supplier which one is best for your style and budget. Always check how each finish changes the quality and materials of your tumbler.

Tip: If you want to spend less, start with single-color powder coating. You can try gradients or electroplating later as your brand grows.

Lid structure complexity

Lid design changes how much your tumbler costs. Simple lids, like screw tops, cost less and are easy to make. If you want leakproof lids, sliders, or auto-seal parts, you pay more for extra pieces and testing. Silicone seals and special shapes also cost more but make the tumbler better to use.

You should think about how much you want to spend on lids. If your customers need travel mugs or tumblers for outside, leakproof lids are worth the extra money. For simple drinkware, basic lids help keep prices low. Always test your lid designs to make sure they fit and work well before you order a lot. Good lids show you care about quality and materials.

Note: Fancy lids can take longer to make. Talk to your supplier about your schedule so you do not have delays.

Packaging upgrade options

Packaging is important for how people see your brand. When you pick packaging for your custom tumblers, you have lots of choices. Each upgrade can change the price, the look, and how customers feel. You want packaging that keeps your tumbler safe and helps it get noticed.

You can use basic packaging if you want to save money. This is usually a plain white or brown box. Basic packaging protects the tumbler when it ships. Many brands use this for big orders or when they want to focus on the tumbler.

If you want to make customers happy, you can pick better packaging. Here are some top choices for 2026:

Custom printed boxes: You can add your logo, brand colors, or pictures. This makes your brand look special and easy to remember.

Gift boxes: These are strong boxes with foam or inserts inside. They are good for company gifts or special sets.

Envases ecológicos: You can use recycled or earth-safe materials. Many people like packaging that helps the planet.

Window boxes: These boxes let people see the tumbler inside. They are great for stores.

Sleeves and wraps: You can put a printed sleeve or wrap around the box. This gives you more ways to show your brand.

Tip: Always ask your supplier for samples of the packaging. You want to check if the quality is good and see how your logo looks.

The table below shows how each packaging upgrade changes cost and how people see your brand:

Packaging Type | Cost Impact | Brand Perception | Best Use Cases |

|---|---|---|---|

Basic Box | Bajo | Simple, functional | Bulk orders, online sales |

Custom Printed Box | Medio | Professional, branded | DTC brands, retail shelves |

Gift Box with Insert | Alta | Premium, gift-ready | Corporate gifts, special sets |

Materiales ecológicos | Medio | Responsible, modern | Green brands, global markets |

When you choose packaging, think about who will buy your tumbler. Some people want simple boxes to save money. Others want a fancy box when they open their tumbler. You can also mix choices, like using eco-friendly stuff for a custom printed box.

Better packaging can cost more, but it adds value. Good packaging keeps your tumbler safe and helps your brand get noticed. You show buyers that you care about quality and small things.

MOQ by Product Type

Stanley-style tumbler MOQ

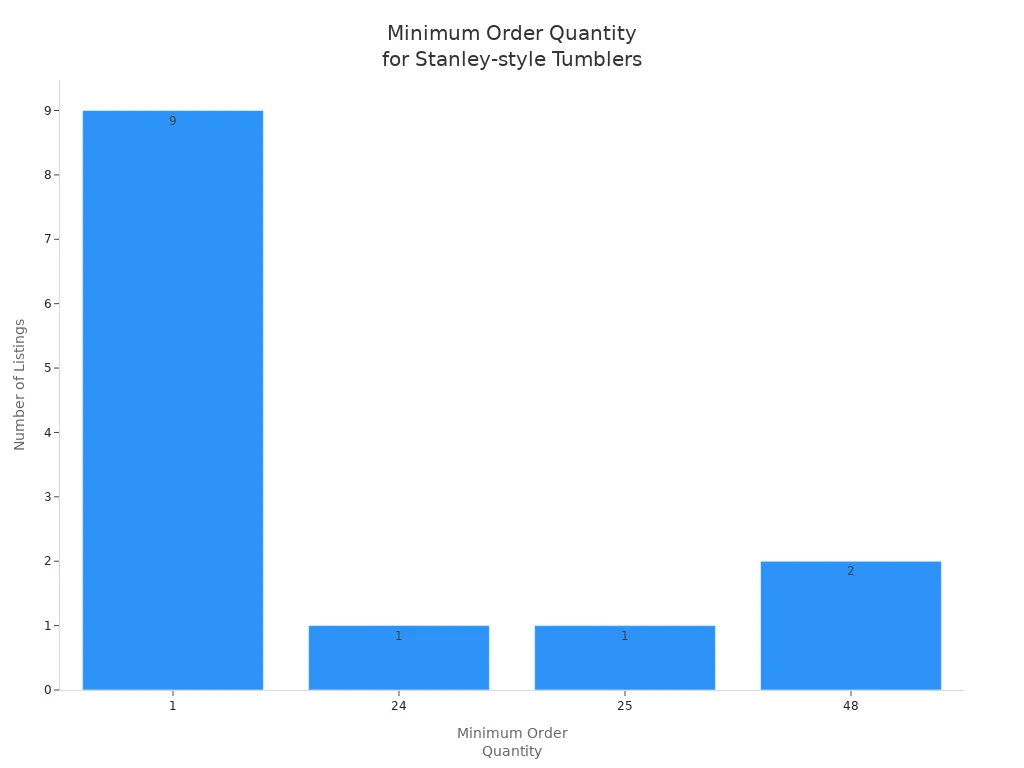

You can start your tumbler brand with a small order. In 2026, top factories let you buy just a few Stanley-style tumblers. You do not have to buy a lot at once. Some suppliers let you get only one tumbler. This is good if you want to test your idea or make a sample. Other styles need more, like 24, 25, or 48 tumblers. The number depends on the style and how you want to customize.

Here is a table that shows the minimum order numbers for Stanley-style tumblers from a main supplier:

Manufacturer | Minimum Order Quantity |

|---|---|

Successories | 1 |

Successories | 25 |

Successories | 48 |

Successories | 24 |

You have lots of choices for your order size. This helps you save money and lower risk when you start new products.

You can order just 1 Stanley-style tumbler.

You can order 25 Custom Gift 30oz Everyday Stan tumblers.

You can order 48 Custom Gift 40oz Value Stan Tumblers.

You can order 24 Employee Wellness Gift 30oz Stanley Quencher H2.0 FlowState tumblers.

Tip: Use flexible moqs and prices to try new colors or limited editions. You will not have too many extras.

YETI-style tumbler MOQ

YETI-style tumblers are strong and keep drinks hot or cold. Most factories ask you to buy between 48 and 100 tumblers for custom YETI-style orders. You can ask for a sample before you buy a lot. This helps you check how good the tumbler is. Some suppliers let you order fewer if you pick basic colors or simple logos. If you want special finishes or lids, you may need to buy more.

Ask your supplier about prices and moqs for YETI-style tumblers. This helps you plan your spending and branding. Many factories now let you order small batches. You can test new ideas or run small campaigns without spending too much.

Note: Small moqs help you change your products fast and listen to what buyers want.

Slim/standard tumblers MOQ

Slim and standard tumblers are good for daily use and stores. Most factories ask for 24 to 50 tumblers for these styles. You can pick many colors and finishes, even with a small order. If you want your logo or special packaging, some suppliers let you start with just 24 tumblers.

Here is a table that shows the usual moqs for slim and standard tumblers:

Tumbler Style | Typical MOQ |

|---|---|

Slim Tumblers | 24 |

Standard Tumblers | 48 |

You can mix colors or lid types in one order to reach the minimum. This lets you give your customers more choices and see which ones they like best.

Tip: Small moqs help you start new tumbler collections or change for holidays easily.

ODM new mold MOQ

When you want to launch a tumbler with a brand-new shape or feature, you need to ask your manufacturer about the ODM new mold MOQ. ODM stands for “Original Design Manufacturing.” This means you create a custom tumbler design that does not exist in the factory’s catalog. The factory must build a new mold just for your product.

You should know that ODM new mold MOQ is usually much higher than standard tumbler MOQ. Factories need to cover the cost of making the mold and setting up production. Most suppliers set the minimum order quantity for ODM molds between 1,000 and 3,000 units. Some high-end factories may ask for even more, especially if your design is complex or uses special materials.

Consejo: If you want to test your design before a big order, ask your supplier for a small batch of samples. This helps you check the quality and make changes before full production.

Here are the main factors that affect ODM new mold MOQ:

Mold complexity: Simple shapes need fewer units. Complex designs with handles, curves, or special lids require more.

Material type: Stainless steel molds cost more than plastic. You may need a higher MOQ for premium metals.

Decoration options: If you want full-wrap printing or special finishes, factories may increase the MOQ.

Factory capacity: Large factories can handle big orders. Small workshops may offer lower MOQs but slower turnaround.

You should always ask for a clear quote and timeline before you start. Factories will give you a mold fee, which can range from $1,500 to $8,000 depending on the design. Some suppliers refund part of the mold fee if you place a large order.

ODM Mold Type | Typical MOQ | Mold Fee Range | Sample Lead Time |

|---|---|---|---|

Simple Tumbler Body | 1,000 | $1,500–$3,000 | 2–4 weeks |

Complex Handle/Lid | 2,000–3,000 | $3,500–$8,000 | 3–6 weeks |

You should plan your launch carefully. If you want to lower your risk, start with a proven mold and add custom colors or logos. When your brand grows, you can invest in a new ODM mold for a signature product.

Nota: Always check if your supplier owns the mold or if you do. If you pay for the mold, you should get a contract that protects your design.

ODM new mold MOQ is a big step for new brands. You get a unique product that helps you stand out. You also need to manage your budget and timeline. Ask questions, get samples, and work with a factory that understands your goals.

QC & Compliance Testing

Insulation testing (hot & cold performance)

You need to check how well your tumblers keep drinks hot or cold. Insulation testing shows if your product meets customer expectations. Factories use strict standards for this test. They fill the tumbler with hot water and measure the temperature loss each hour. For cold drinks, they use ice water and check how long it stays cold. The best tumblers lose less than 1°C per hour. You should ask your supplier for test results before you order. This helps you compare products using references and reviews from other brands.

Here is a table showing the main QC standards for insulation:

Test Parameter | Standard Requirement |

|---|---|

Vacuum Level | >99.9% |

Heat Retention | <1°C loss per hour |

Seal Integrity | Zero leakage at 5 PSI |

You want your tumblers to pass these tests. Good insulation means happy customers and fewer returns.

Leakproof & drop testing

Leakproof testing checks if your tumbler lid keeps liquids inside. You fill the tumbler, close the lid, and turn it upside down. The factory shakes it and looks for leaks. Seal integrity must meet zero leakage at 5 PSI. You should always ask for leakproof test results before you buy. Drop testing shows if your tumbler can survive daily use. Workers drop the tumbler from a set height onto a hard surface. They check for dents, cracks, or broken handles. For 40oz models, handle strength tests make sure the handle does not break under weight.

Factories run these tests during production. They use incoming material inspection to check all materials before making tumblers. In-line production checks help catch problems early. Final QC and random sampling standards find hidden issues before shipping. You can trust suppliers who share references and reviews from past clients.

Tip: Always request a QC report with photos and test results. This helps you see how your tumblers perform in real life.

Dishwasher durability testing

Dishwasher durability testing checks if your tumbler keeps its color and finish after many washes. Factories put tumblers through several dishwasher cycles. They look for fading, peeling, or scratches on the coating. The coating adhesion test and scratch resistance test show if the finish stays strong. You want tumblers that pass these tests so your brand looks good after months of use.

You should ask your supplier about dishwasher cycle tests. Good suppliers use certified materials that resist heat and water. They provide certifications like LFGB, Prop 65, and BPA-Free to prove safety for food and drinks. Always check references and reviews to see how other brands rate the durability of their tumblers.

Note: Tumblers with strong coatings and safe materials last longer and keep your customers happy.

FDA / LFGB material safety requirements

You must make sure your tumblers meet strict safety standards before you sell them. The two most important certifications for drinkware are FDA (Food and Drug Administration) and LFGB (Lebensmittel- und Futtermittelgesetzbuch). These rules protect your customers from harmful chemicals and unsafe materials.

FDA requirements apply in the United States. The FDA checks if your tumbler materials are safe for food and drinks. You need to use stainless steel, silicone, and coatings that do not leach toxins. The FDA tests for heavy metals, BPA, and other dangerous substances. If your tumblers pass, you can sell them in the U.S. with confidence.

LFGB requirements are the gold standard in Europe. LFGB tests are even stricter than FDA rules. They check for chemicals, odors, and taste transfer. If your tumblers pass LFGB, you show buyers in Germany and the EU that your products are safe and high quality.

Consejo: Always ask your manufacturer for FDA and LFGB certificates. Request recent test reports for each batch. This protects your brand and builds trust with your customers.

He aquí una rápida comparación:

Standard | Region | What It Tests For | Why It Matters |

|---|---|---|---|

FDA | Estados Unidos | Heavy metals, BPA, toxins | Legal for U.S. sales |

LFGB | Europe | Chemicals, odor, taste transfer | Trusted in EU and globally |

You should also check for other marks like Prop 65 (California), REACH (EU), and BPA-Free. These extra labels help your brand stand out in a crowded market.

How to verify compliance:

Ask for official certificates from your supplier.

Check the test date and the testing lab’s name.

Make sure the certificate matches your product’s material and color.

Keep copies for your records and for customs checks.

If you skip these steps, you risk recalls, fines, or bad reviews. Always put safety first when you choose a tumbler manufacturer.

Adhesion test for coating & printing

You want your custom tumblers to look great after months of use. The adhesion test checks if the coating and printed logos stay on the tumbler. This test is key for quality control.

Factories use special tools to scratch or tape-test the surface. They check if the paint, powder coating, or printed logo peels off. If the finish comes off easily, the factory must fix the process. Strong adhesion means your tumbler keeps its color and branding, even after washing or daily use.

Common adhesion tests:

Tape test: Workers press sticky tape on the logo or coating, then pull it off fast. If the design stays, it passes.

Scratch test: Workers use a tool to scratch the surface. The coating should not flake or peel.

Dishwasher test: Tumblers go through several wash cycles. The finish should not fade or chip.

Nota: Always ask your supplier for adhesion test results. Request photos or videos of the tests for your records.

Here is a simple checklist for adhesion quality:

The logo does not peel after tape test.

The coating does not scratch off with a coin.

The color stays bright after five dishwasher cycles.

If your tumblers pass these tests, you can promise your customers long-lasting quality. Adhesion testing helps your brand avoid complaints and keeps your products looking new.

Tips to Reduce Cost Without Lowering Quality

Use existing molds instead of custom ODM

You can save money if you pick existing molds for your tumblers. Factories have many mold designs ready to use. When you choose these, you do not pay high fees or wait a long time. Custom molds, called ODM, cost more because the factory must make new tools just for you. If you pick a design from the factory’s catalog, you get good quality and faster results.

Consejo: Ask your manufacturer to show you their mold library. You might find a style you like without paying extra.

Using existing molds also helps you avoid mistakes in design. Factories have tested these molds many times before. You get a tumbler that works well and is safe to use. This way, you can sell your product faster and with less risk.

Choose simpler lids for lower cost

The lid you pick changes the price and how good your tumbler is. Simple lids, like screw-on or snap lids, are cheaper to make. Lids with sliders, flip tops, or auto-seal parts need more pieces and testing. These extras make the tumbler cost more and take longer to make.

Pick a lid that fits what your customers want. If people just need a basic tumbler for home or work, a simple lid is fine. For travel mugs, you can use a leakproof lid, but keep it easy to put together. Simple lids also have fewer leaks or breaks.

Nota: Always check the lid to make sure it fits and works before you order a lot.

Use standard factory colors to reduce MOQ

The color you choose can change your costs and how many you must buy. Factories have standard colors they make in big batches. If you pick these colors, you can buy fewer tumblers and still get a good price. Custom colors need special mixing, which means you must buy more and pay more for each one.

You can use standard colors to see what people like or start a new collection. If your tumblers sell well, you can add custom colors later. Standard colors also help you get your order faster because the factory already has the paint.

Here is a table that shows some of the best ways to save money without making your tumblers worse:

Estrategia | Descripción |

|---|---|

Leverage existing mold libraries | Use molds the factory already has to save money and time. |

Optimize designs with manufacturer expertise | Work with your supplier to fix designs and avoid mistakes. |

Manage order volumes effectively | Buy more tumblers at once to pay less for each one. |

Ensure advanced planning | Plan early to keep costs low and avoid extra fees. |

If you follow these tips, your tumblers stay good and your costs stay low. You also work better with your manufacturer, which helps your brand grow.

Combine multiple SKUs to reach better pricing

You can lower your tumbler costs by combining multiple SKUs in one order. SKU stands for “Stock Keeping Unit.” Each SKU is a different product, color, or style. When you order more SKUs together, you increase your total quantity. Factories often give you better prices when you buy more units at once.

You might want to launch several tumbler styles, colors, or lid types. If you order each SKU separately, you pay a higher price for each one. When you combine them, you reach higher price breaks. This helps you save money and get more value for your brand.

Here is how you can use this strategy:

Group different tumbler sizes, like 20oz and 30oz, in one order.

Mix colors, such as black, white, and blue, to reach the factory’s price tier.

Add various lid options, like flip and slider lids, to your order.

Include seasonal or limited-edition designs with your main SKUs.

Consejo: Ask your supplier if they allow mixed SKUs to count toward the total quantity for bulk pricing. Many factories support this, especially for new brands.

Benefits of combining SKUs:

You get lower unit costs.

You offer more choices to your customers.

You test which styles sell best without spending too much.

You reduce the risk of unsold inventory.

Example Table: How Combining SKUs Impacts Pricing

SKU Type | Units Ordered | Price per Unit | Coste total |

|---|---|---|---|

Single SKU | 100 | $7.00 | $700 |

3 Mixed SKUs | 300 (100 each) | $6.00 | $1,800 |

You see that the price per unit drops when you order more SKUs together. This helps you stretch your budget and grow your product line.

You should plan your launch with several SKUs. You can use this method for new colors, lid types, or packaging options. If you want to test the market, start with small batches of each SKU. As you learn what sells, you can increase your order size and get even better pricing.

Nota: Always confirm with your supplier how they count mixed SKUs for pricing. Some factories have rules about minimums for each style or color.

Combining SKUs is a smart way to save money and build a strong brand. You get more options for your customers and better deals from your manufacturer.

How to Choose the Right Custom Tumbler Manufacturer

Factory qualifications to check

You want to pick a custom tumbler manufacturer with high standards. When you search for a tumbler supplier, look at their factory qualifications first. Good factories have strong quality checks. These checks make sure every custom tumbler is safe and always the same. You should ask for certificates like LFGB, Prop 65, and BPA-Free. These papers show the tumblers are safe for food and drinks. It is important for the supplier to be open about their process. You need to see clear records and honest answers from them. This helps you trust them and follow the law.

Here is a table to help you compare factory qualifications:

Qualification | Importance |

|---|---|

Quality Control System | Ensures consistent product safety and quality |

Certifications (LFGB, Prop 65, BPA-Free) | Validates safety for food and drink use |

Supplier Transparency | Builds trust and ensures compliance |

You should always check these things before you pick a tumbler supplier. If you skip this, you might get bad custom products.

How to evaluate vacuum insulation quality

Vacuum insulation is very important in most custom tumblers. You need to make sure your tumbler supplier uses the best ways to make it. Ask them how they do their vacuum process. Good suppliers will show you test results for keeping drinks hot or cold. You should ask for a sample and do your own tests. Fill the tumbler with hot water and check the temperature after six hours. Try again with cold water and ice. If the tumbler keeps drinks hot or cold, the insulation is good.

Look for suppliers who share their QC reports. These reports should show insulation and drop test results. You can also read reviews from other brands. Reviews help you see if the custom tumbler manufacturer does what they say. If you see lots of complaints about bad insulation, pick a different tumbler supplier.

Important sample approval steps

You must approve a sample before you buy a lot. You need to see and test a real custom tumbler from your supplier. Ask for a sample with your logo and finish. Check the color, print, and if the lid fits well. Do leak tests and insulation tests yourself. If the sample is good, you can order more with confidence.

Read reviews from other buyers about the sample step. Good suppliers send samples fast and answer your questions. If you find slow replies or bad service, look for another tumbler supplier. Always write down your sample test results. This helps you compare different custom tumbler manufacturers and choose the best one.

Tip: Never skip the sample step. A good sample saves you money and keeps your brand safe.

Red flags that indicate an unreliable supplier

You should look out for warning signs when picking a custom tumbler manufacturer. Some suppliers seem fine at first but have problems later. If you notice these red flags, you should be careful before working with them.

Common red flags are:

Poor communication: The supplier does not reply fast. Their answers are not clear or are missing details. You might feel confused after talking to them.

No certifications: The factory cannot show safety or quality certificates. If you ask for FDA, LFGB, or BPA-Free papers, they do not give them to you.

Unwilling to send samples: The supplier will not send you a sample. They make excuses or want a lot of money for one. You cannot check the product before you buy.

Hidden costs: The price looks low at first, but later there are extra fees. You see new charges for packaging, molds, or shipping that were not in the first price.

Poor reviews or no references: You cannot find good reviews online. Other brands say their orders were late, missing, or bad quality. The supplier does not give you any references.

No factory visits allowed: The supplier will not let you visit their factory. They do not want to do video calls or show pictures of their production line.

Unclear payment terms: The payment rules are confusing. The supplier wants all the money before making your order. They do not use safe ways to pay.

Low transparency: The supplier does not tell you about their process. You cannot see how they check quality or where they get materials.

Consejo: If you feel something is wrong with a supplier, trust your gut. Good manufacturers answer questions, share papers, and help you understand every step.

You can use this table to check for red flags when you talk to a new supplier:

Red Flag | What You See | Why It Matters |

|---|---|---|

Poor Communication | Slow or unclear replies | Hard to solve problems |

No Certifications | Missing safety documents | Risk of unsafe products |

Refuses Samples | No samples or high sample fees | Cannot check quality |

Costes ocultos | Extra fees after first quote | Budget problems |

Bad Reviews | Complaints from other brands | Risk of late or bad orders |

No Factory Visits | No tours or video calls | May hide poor conditions |

Unclear Payments | Confusing or risky payment terms | Risk of losing money |

Low Transparency | No details about process or QC | Hard to trust supplier |

If you see one or more of these signs, you should find another manufacturer. Good suppliers want you to trust them and help your brand grow. They share info, send samples, and answer your questions. You keep your business safe when you pick a reliable partner.

To pick the best custom tumbler manufacturer, you need to do a few things. First, think about what your brand wants and how good you want your tumblers to be. Next, look at what the supplier can do and ask them for samples. Try talking with the supplier to see if they answer your questions well. Make sure you check their certificates to see if their products are safe. Be careful if you see warning signs before you choose who to work with.

Good business partners trust each other and have clear plans. Start looking for your supplier now by following these steps. This will help your brand become strong and special for a long time.