Choosing the right Glass Shaker Bottle Manufacturer – OEM & Private Label shapes your product’s success. You need a partner with proven experience, high quality standards, and the ability to deliver custom solutions. Understanding your product requirements and your target audience helps you make better decisions. The style, closure, and sustainability of your bottle influence how people see your brand and use your product.

Principales conclusiones | Impact on Brand Perception and User Experience |

|---|---|

Bottle finishes match closures for better seals | Prevents leaks and keeps products fresh, building trust |

Unique finishes improve usability | Creates positive experiences and encourages repeat purchases |

Makes your brand memorable and stands out in the market |

Evaluating each manufacturer step by step helps you make a smart choice.

Principales conclusiones

Choose a manufacturer with proven experience to ensure product reliability and quality.

Define your product requirements based on your target audience to create a successful product.

Select eco-friendly materials to build trust and appeal to environmentally conscious consumers.

Request samples to test durability and fit before placing a large order, avoiding costly mistakes.

Ensure clear communication about pricing, minimum orders, and delivery timelines to manage your budget effectively.

Glass Shaker Bottle Manufacturer – OEM & Private Label

Experience & Industry Reputation

You want a Glass Shaker Bottle Manufacturer – OEM & Private Label with a strong history and proven expertise. Manufacturers with over ten years in the industry often deliver reliable products. You can check their experience by looking at how long they have produced glass bottles and how many clients they have served. A company’s reputation grows when it uses high-quality materials and follows strict quality control standards. You should also look for a wide range of products and printing methods. These show that the manufacturer can meet different needs.

Criteria | Descripción |

|---|---|

Level of Experience | The manufacturer’s history and duration in the industry, indicating reliability and expertise. |

Commitment to Quality | Use of high-quality materials and stringent quality control standards to ensure product excellence. |

Range of Products and Methods | Variety in product offerings and printing methods that cater to diverse customer needs. |

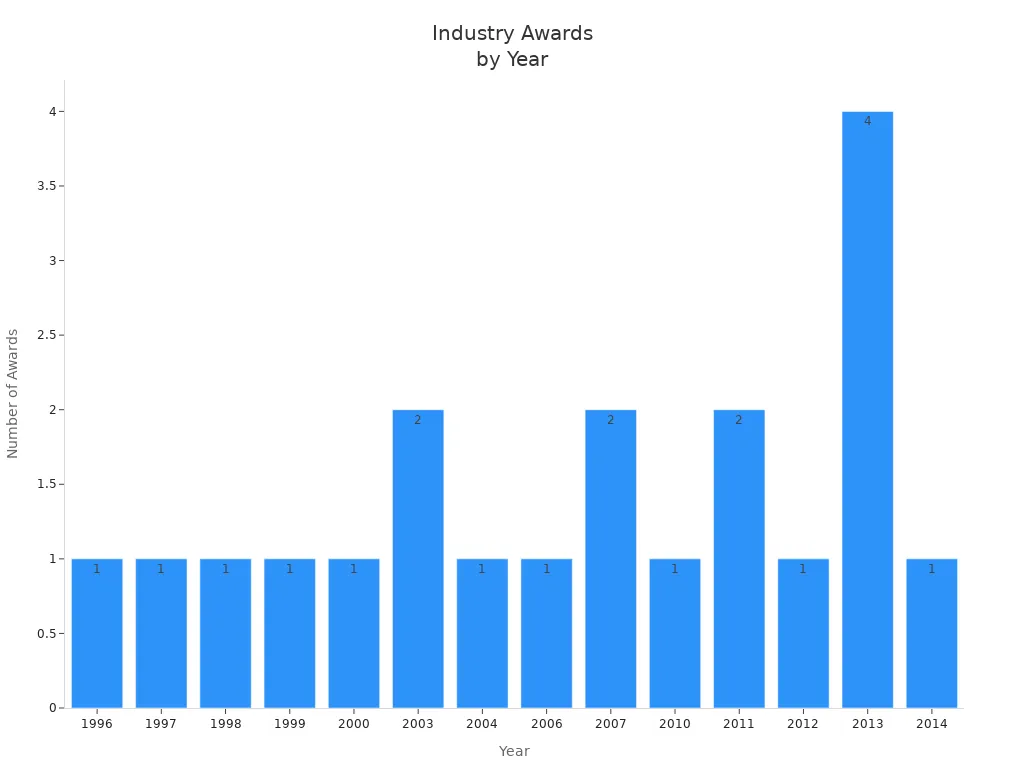

You can also check for awards and third-party reviews. Industry awards show that the manufacturer stands out for design and quality. Reviews from other brands help you see if the company delivers on its promises. Here is a chart showing how many awards a top manufacturer has won over the years:

Tip: Ask for references from past clients and check for awards or certifications. This helps you confirm the manufacturer’s reputation.

Product Requirements & Target Audience

You need to define your product requirements before choosing a Glass Shaker Bottle Manufacturer – OEM & Private Label. Think about the size, shape, and material of the bottle. Decide if you want a simple design or something unique. Your target audience matters. Athletes may want bottles with easy-to-use closures. Health-conscious buyers may prefer glass bottles that are BPA-free. Kids need bottles with leak-proof lids and bright colors. You should list your must-have features and match them to your audience’s needs.

Choose bottle sizes that fit your customers’ routines.

Select materials that match your brand’s promise of safety and quality.

Pick closure types that suit your target users, like flip tops for quick access or screw caps for secure sealing.

Note: Understanding your audience helps you create a product that stands out and meets their expectations.

Brand Style & Closure Options

Matching bottle style and closure options to your brand identity builds customer loyalty. You want your Glass Shaker Bottle Manufacturer – OEM & Private Label to offer choices that reflect your brand. Consistent color schemes make your products easy to recognize. A cohesive look through color matching increases brand recognition. Unique bottle designs and coordinated closures show your attention to detail. Tamper-evident closures give buyers confidence in product safety.

Consistent color schemes help your brand stand out.

A well-designed bottle acts as a canvas for your brand expression.

Coordinated closures convey safety and influence buying decisions.

Color psychology can evoke emotions and strengthen brand impact.

Strategic use of color fosters deeper connections with consumers.

Tip: Work with your manufacturer to create a unified image. This helps your brand become memorable and encourages repeat purchases.

Quality & Safety Standards

Choosing a Glass Shaker Bottle Manufacturer – OEM & Private Label means you must pay close attention to quality and safety. You want bottles that are safe for food and drinks. You also want to make sure the bottles meet strict standards in the United States and Europe. This section will help you understand what to look for.

Material Testing & Certifications

You need to check if the manufacturer uses food-grade certified materials. This keeps your customers safe and builds trust in your brand. Most countries require glass shaker bottles to pass certain tests before they reach the market. These tests make sure the bottles do not contain harmful chemicals like BPA, lead, or cadmium.

Testing Standard | Descripción |

|---|---|

Ensures materials are safe for food contact. | |

EU | Complies with European safety regulations. |

California Proposition 65 | Limits exposure to harmful chemicals like lead and cadmium. |

Certifications also show that a manufacturer takes safety seriously. Look for these common certifications:

Certificación | Importance |

|---|---|

FDA | Ensures product safety and compliance with food contact standards |

LFGB | Certifies adherence to food safety regulations |

SGS | Validates quality management and ethical manufacturing practices |

Tip: Always ask for proof of certifications. This helps you confirm that the manufacturer meets all safety rules.

Quality Control & Transparency

You want a manufacturer that follows strict quality control steps. Good manufacturers check every batch of bottles for clarity and strength. They use inspection protocols to make sure each bottle looks clear and has no more than three visible imperfections per 100 units. Clean assembly areas help prevent scratches and keep bottles looking new.

Manufacturers must follow food safety standards in the US and EU.

They should use food-grade certified materials.

A strict quality control process is important during manufacturing.

Supplier audits check for dust-free assembly lines to avoid micro-scratches.

Leading suppliers offer quick responses to any quality claims and provide after-sales support, such as mold maintenance agreements.

You should also check if the manufacturer shares details about their quality checks. Transparency builds trust and helps you avoid problems later.

Note: Ask about the manufacturer’s inspection process and how they handle defects. This shows how much they care about quality.

Requesting Samples

Before you place a large order, you should always request samples. Samples let you test the bottle’s durability, clarity, and closure fit. You can also check if the bottle matches your brand’s needs.

Tipo de prueba | Detalles |

|---|---|

Availability of Existing Samples | Standard bottles can be sampled before bulk orders. |

Pre-production Samples | Custom projects can receive samples after mold approval. |

Shipping Costs and Lead Times | These will be confirmed on a case-by-case basis. |

When you get samples, check for leaks, cracks, and how the closure fits. Test the bottle with real drinks to see if it holds up in daily use. This step helps you avoid costly mistakes and ensures your customers get a safe, high-quality product.

Tip: Always test samples under real-life conditions. This helps you spot any issues before you commit to a full order.

Customization & Sustainability

OEM & Private Label Options

You can create a unique product by choosing custom options for your glass shaker bottles. Manufacturers offer many ways to personalize your bottles. You select the size, shape, color, and logo. Custom designs help your brand stand out. You also decide how many bottles you want to order. Minimum order quantities affect your project’s feasibility.

Minimum order quantity for custom glass shaker bottles is 100 pieces.

The first tier quantity is the standard minimum. You can request a lower minimum, but extra costs may apply.

Custom projects let you match your bottle to your brand and your customers’ needs. You get more control over the look and feel of your product.

Eco-Friendly Materials & Practices

You build trust with your customers when you use eco-friendly materials. Glass is a top choice for sustainability.

Glass is one of the most sustainable materials available. It is 100% recyclable and can be reused indefinitely without degrading in quality.

Sustainable manufacturing practices make your product more attractive in the market.

The market for glass shaker bottles is increasingly influenced by sustainable practices.

Consumer preferences are shifting towards eco-friendly products, especially in Europe.

Countries like Germany and France focus on recyclable materials and eco-certifications.

The global market for protein shaker bottles is seeing a trend towards sustainability.

Many brands use eco-conscious materials, such as BPA-free plastics and biodegradable components.

You show your commitment to the environment by choosing these materials and practices.

Packaging & Branding Solutions

Packaging and branding solutions help your product look professional and trustworthy. Top manufacturers offer many options for customization and branding.

Opciones de personalización | Special Features | |

|---|---|---|

Everich Hydro | Full OEM & ODM customization including design, materials, colors, logos, and packaging | Over 20 years of expertise, strict quality control, certified to LFGB, FDA, and BPA-free standards. |

LaiKoe | Silk screen printing, UV printing, heat transfer printing, in-mold labeling | Flexible OEM/ODM capabilities, reliable production. |

Charmlite | Customization with branding, colors, and packaging | Expertise in wholesale protein shaker bottles, strict quality control. |

ProSHAKE | OEM/ODM projects for custom shaker bottles | Focus on high-quality, user-friendly designs, collaboration with major sports nutrition brands. |

Master Shaker | Full branding services including designs, colors, and logos | Experienced QC team overseeing production stages from sourcing to shipping. |

Custom packaging boosts your brand image and builds consumer trust. Design elements like curvature and material choice communicate your brand values. Unique designs attract attention and improve brand favorability. Transparent packaging lets consumers see the product, increasing credibility. Over 80% of consumers say transparency affects their choices.

Tip: Work with your manufacturer to create packaging that matches your brand and appeals to your customers.

Order Flexibility & Support

Minimum Orders & Lead Times

You need to know the minimum order quantity before you start working with a manufacturer. Most companies set a minimum number of bottles for each order. This helps them manage production costs and keep prices fair. If you want a custom design, the minimum order might be higher. Lead times show how long it takes to make and deliver your bottles. You should ask about production schedules and delivery dates. Some manufacturers can rush orders for special projects. Clear communication helps you plan your launch and avoid delays.

Tip: Always ask for a timeline and minimum order details before you confirm your project.

Logistics & After-Sales Service

Reliable logistics and strong after-sales support make your experience smoother. You want your bottles delivered on time and in good condition. Many brands value these services:

Customer-centric warehousing solutions

Comprehensive after-sales support including DDP (Delivery Duty Paid) services

You should check if the manufacturer offers tracking for shipments. Warehousing solutions help you store bottles until you need them. After-sales support solves problems quickly if you find defects or need replacements. DDP services mean the manufacturer handles customs and taxes, so you get your products without extra hassle.

Note: Good logistics and after-sales service protect your investment and keep your customers happy.

Pricing & Payment Terms

Understanding pricing and payment terms helps you manage your budget. Manufacturers usually follow a clear process:

Paso | Descripción |

|---|---|

Confirm Sample | After receiving the sample, confirm if it meets your requirements. |

Pay The Deposit | Pay a deposit after sample confirmation to start production. |

Check All Products | Arrange for inspection of the products after production. |

Delivery | Utilize a cooperative forwarder for transportation or use your own. |

Confirm Products | Unpack and check for any issues upon receiving the product. |

Finish Order | Notify completion of the order if there are no problems with the product. |

You pay a deposit to start production. After you check the samples and products, you pay the balance. Some manufacturers let you use your own shipping company. Others offer help with delivery. Always review payment terms and ask questions if you need more details.

Tip: Clear payment steps and fair pricing help you build trust with your manufacturer.

Choosing the right glass shaker bottle manufacturer shapes your brand’s future. You should focus on experience, product quality, customization, sustainability, and strong support. Create a checklist to guide your search:

Define your target market and purpose

Determine product specifications

Research and shortlist potential suppliers

Request samples for evaluation

Verify supplier certifications and compliance

Negotiate terms and finalize the order

Plan for post-purchase marketing and distribution

A careful review helps you build a trusted product and grow your business.

PREGUNTAS FRECUENTES

What certifications should you look for in a glass shaker bottle manufacturer?

You should check for FDA, LFGB, and SGS certifications. These prove the bottles are safe for food and drinks. Ask the manufacturer for proof before you place an order.

How can you test the quality of glass shaker bottles before buying?

Request samples from the manufacturer. Test for leaks, cracks, and closure fit. Use the bottles with real drinks to see if they meet your standards.

What is the typical minimum order quantity for custom glass shaker bottles?

Most manufacturers require at least 100 bottles for custom orders. Some may offer lower minimums, but extra costs may apply. Always confirm before starting your project.

Can you customize the packaging and branding for your glass shaker bottles?

Yes, you can choose colors, logos, and packaging styles. Work with your manufacturer to design packaging that matches your brand and attracts customers.